As a retailer looking to stock sharpening stones, understanding the various types available is crucial to meeting your customers’ diverse needs.

There are several types of sharpening stones available, including oil stones, water stones, diamond stones, and ceramic stones, each with unique characteristics and benefits.

Factors such as the variety of tools your target market uses, the sharpening precision they require, and regional preferences all play a role in determining which stones will be most profitable for your business.

By offering a diverse selection, including options from trusted sharpening stone manufacturers, you can cater to a wide range of customer needs and maximize your sales potential.

What Is A Sharpening Stone (Whetstone)?

A sharpening stone, also known as a whetstone, is a tool used to sharpen and hone the edges of knives, tools, and other cutting implements. These stones come in various shapes, sizes, and materials, each designed for specific sharpening needs.

Sharpening stones work by grinding away small amounts of metal from the blade’s edge, creating a sharp, uniform cutting surface. You’ll find them in both natural and synthetic materials, with grit sizes ranging from coarse to ultra-fine.

When using a whetstone, you typically need to lubricate it with either water or oil. This helps to prevent metal particles from clogging the stone’s surface and ensures smooth sharpening.

Whetstones are classified by their grit size, which indicates how coarse or fine the stone’s surface is. Lower grit numbers (around 1000) are coarser and used for initial sharpening, while higher grit numbers (8000+) are finer and used for polishing and refining the edge.

You can find whetstones in various sizes, but the most common dimensions are:

- Length: 6-8 inches

- Width: 2-3 inches

- Thickness: 1 inch

By understanding the basics of sharpening stones, you’ll be better equipped to choose the right products for your inventory and assist your customers in maintaining their cutting tools effectively.

Buy wholesale or custom Sharpening Stone from China

Types of Sharpening Stones

1. Natural Stones

Natural stones are quarried directly from the earth. They offer unique sharpening properties but often come at a higher price. Two types stand out in the market:

- Japanese Natural Water Stones

Known as “Tennen Toishi,” these stones come from specific regions in Japan. They create extremely sharp edges, making them a favorite for high-end kitchen knives.

- Arkansas Stones

Found in Arkansas, USA, these stones are prized for their durability and fine grits. You can use them with oil or water.

2. Synthetic Stones

Synthetic stones are man-made and offer consistent grit levels. They’re often more affordable and easier to maintain than natural stones:

- Oil Stones

Oil stones use oil as a lubricant during sharpening. They’re durable and great for beginners.

you’ll find they’re often made of Aluminum Oxide or Silicon Carbide. If you see Novaculite mentioned, that’s a natural material commonly used in oil stones.

- Synthetic Water Stones

Synthetic Water stones require water for lubrication. They cut faster than oil stones but wear down quicker. The popular King whetstone falls into this category.

For synthetic water stones, look for Aluminum Oxide or Silicon Carbide in the description. You might also come across high-quality stones using magnesia-bonded abrasives.

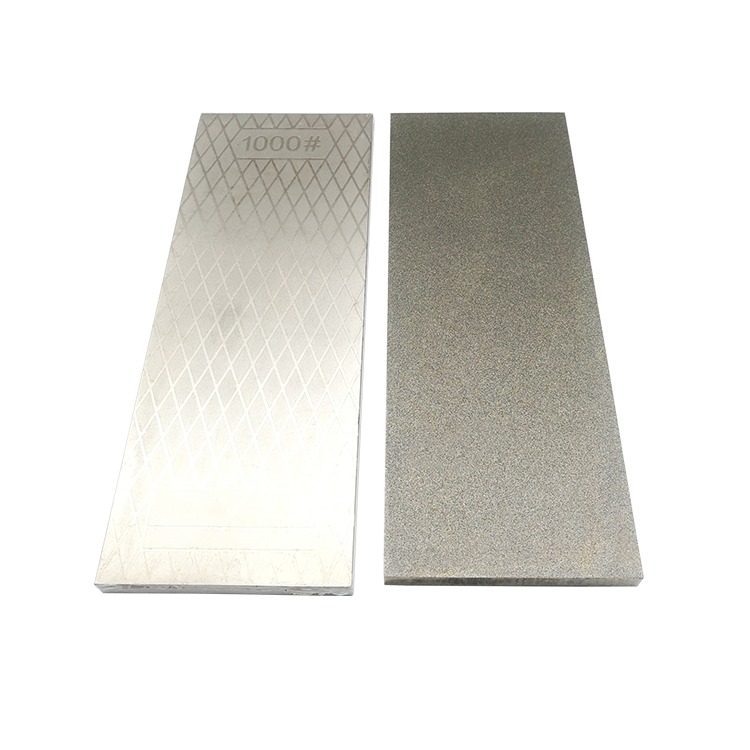

- Diamond Stones

Diamond stones are the hardest and most durable. They sharpen quickly and don’t need flattening. However, they’re typically more expensive.

When shopping for diamond stones, you’ll see a metal or resin base with diamond particles. Keep an eye out for terms like “monocrystalline” or “polycrystalline” diamonds.

- Ceramic Stones

Ceramic stones are hard and don’t need lubricant. They’re great for finishing and polishing edges.

If you’re interested in ceramic stones, you’ll mostly find ones made of Aluminum Oxide. Some might be made of Zirconium Oxide or a mix of both.

When you’re starting your sharpening stone business, understanding the different grades is crucial.

Sharpening stones come in various grits, which determine how quickly they remove metal and how fine the resulting edge will be.

Lower grit numbers (around 1000) are coarser and used for initial sharpening, while higher grit numbers (8000+) are finer and used for polishing and refining the edge.

Coarse stones remove material quickly but leave a rough edge. Fine and extra fine stones work more slowly but produce a smoother, sharper edge.

Here’s a breakdown of the main sharpening stone grades:

- Coarse (100-400 grit): Aggressive, fast-cutting stones for repairing damaged blades

- Medium (800-1500 grit): Ideal for general sharpening and maintenance

- Fine (2000-5000 grit): Refines the edge for a sharper finish

- Extra Fine (6000-8000 grit): Polishes the edge for a razor-sharp result

- Ultra Fine (10000+ grit): Creates a mirror-like finish, mostly used by professionals

You’ll want to stock a range of grades to meet different customer needs. Many sharpening enthusiasts use a progression, starting with coarser grits and moving to finer ones.

Double-sided stones with two different grits on each face are popular among beginners. They offer versatility in a single product.

Remember, harder and denser stones tend to wear more slowly, which can be a selling point for your customers looking for long-lasting tools.

Buy wholesale or custom Sharpening Stone from China

Comparison of Sharpening Stone Properties

Sharpening stones come in various types, each with unique characteristics. Let’s explore the key aspects to consider when choosing stones for your business.

Grit ranges

- Oil stones: 100-1200 grit

- Water stones: 220-8000 grit

- Diamond stones: 120-1200 grit

- Ceramic stones: 400-8000 grit

Unlike water stones, which can go up to 8000 grit for ultra-fine polishing, diamond stones and oil stones focus on efficiency and durability in sharpening harder materials.

Hardness and Durability

How long a stone lasts depends on how hard it is. Harder stones usually last longer. Some stones wear down faster and need more care.

- Soft stones (e.g., some water stones): Wear faster, create slurry quickly

- Hard stones (e.g., Diamond stones, Arkansas stones, Ceramic stones): More durable, maintain flatness longer

Price ranges

- Budget-friendly: $20-$50 (basic oil stones, some water stones)

- Mid-range: $50-$150 (quality water stones, some diamond plates, basic ceramic stones)

- Premium: $150-$500+ (high-end synthetic stones, natural water stones, premium ceramic stones)

Maintenance

Some stones need more care than others. This depends on how the stone wears down when you use it. Softer stones usually need more care.

- Diamond stones require the least maintenance

- Oil stones need occasional flattening and regular cleaning

- Water stones (both natural and synthetic) require the most maintenance, needing frequent flattening.

- Arkansas stones also require regular cleaning with oil or water to maintain good sharpening performance.

Here’s a comparison table to help you visualize the differences:

| Stone Type | Grit Range | Hardness | Price Range | Maintenance |

| Oil Stones | 100-1200 | Medium | $20-$100 | Low |

| Water Stones | 220-8000 | Soft-Medium | $30-$300 | Moderate |

| Diamond Stones | 120-1200 | Very Hard | $50-$200 | Low |

| Arkansas Stones | 400-8000 | Hard | $40-$150 | Low |

| Ceramic Stones | 400-8000 | Hard | $30-$250 | Low |

When choosing stones for your business, consider your target market’s needs. Beginners may prefer affordable water stones, while professionals might seek high-end synthetic or natural options.

Remember to stock flattening stones or diamond plates for maintenance. These help keep your stones flat and effective, ensuring customer satisfaction with their purchases.

Best Application Of Different Sharpening Stones

Oil stones are ideal for sharpening pocket knives and other everyday tools. They’re great for beginners due to their ease of use. You can use them to maintain the edge on your EDC knife or repair slightly damaged blades.

Water stones excel at sharpening kitchen knives. They create a sharp, polished edge perfect for precise cutting. You’ll find them particularly useful for Japanese-style knives that require a fine edge.

Diamond stones are versatile and work well for both kitchen and outdoor knives. They’re especially effective for repairing dull knives or those with chips. Use them on your hunting knives or heavy-duty kitchen cleavers.

Ceramic stones are great for finishing and polishing edges. They’re perfect for maintaining already sharp knives. Use them on your high-end chef’s knives or straight razors for a mirror-like finish.

For budget-conscious sellers, combination stones offer versatility. These typically feature different grits on each side, allowing you to both sharpen and refine edges with a single stone.

Remember to consider stone size when choosing. Small 3″ stones work well for pocket knives, while 11.5″ stones are better suited for large kitchen knives.

Pair your stones with accessories like angle guides for consistent results. Cut-resistant gloves can improve safety during sharpening sessions.

Buy wholesale or custom Sharpening Stone from China

Frequently Asked Questions

Sharpening stones come in various types and materials, each with unique properties. Understanding the differences can help you choose the right stone for your needs and business.

How are natural sharpening stones different from synthetic ones?

Natural sharpening stones are quarried from the earth and offer a unique cutting experience. They tend to be more expensive and rare. Synthetic stones are manufactured to precise specifications, ensuring consistent performance.

Natural stones often have a softer feel and can create a finer edge. Synthetic stones typically cut faster and are available in a wider range of grits.

Which stone is best for knife sharpening?

The best stone for knife sharpening depends on the knife’s condition and intended use. For dull knives, start with a coarse grit (around 1000) to remove metal quickly.

Medium grits (3000-5000) refine the edge. Finish with a fine grit (8000+) for a polished edge. Water stones are popular for their fast cutting action and ability to create a sharp burr.

How to find suppliers and manufacturers of whetstone from China?

To find Chinese whetstone suppliers, attend international trade shows focused on kitchenware or abrasives. Online platforms like Alibaba and Global Sources also list many manufacturers.

For a comprehensive overview of leading manufacturers, refer to our article on the Top 10 Sharpening Stone Manufacturers.

Research potential suppliers thoroughly. Request samples to test quality before placing large orders. Consider working with a sourcing agent to navigate language barriers and ensure product quality.

What are the advantages of China sharpening stone suppliers?

Chinese suppliers often offer competitive pricing due to lower production costs. Many have years of experience in manufacturing sharpening stones.

You’ll find a wide variety of stone types and grits available. Some suppliers offer customization options for private labeling. Quick production times can help you maintain inventory levels efficiently.

For bulk purchasing strategies, don’t miss our page on Wholesale Sharpening Stones, which offers valuable insights.

Buy wholesale or custom Sharpening Stone from China

How do I start my sharpening stone business?

Begin by researching the market and identifying your target customers. Decide on the types of stones you want to sell based on demand and your expertise.

Source high-quality stones from reputable Sharpening Stone Manufacturers. Create a business plan outlining your marketing strategy and sales channels. Consider starting with online sales through e-commerce platforms to minimize initial costs.

Develop educational content to help customers choose and use sharpening stones. This builds trust and positions you as an expert in the field.

Choosing the right sharpening stones is crucial for your business success. You now have a solid understanding of the main types: oil stones, water stones, and diamond stones. Each has its unique benefits and applications.

Remember, oil stones are great for beginners and budget-conscious buyers. Water stones offer faster sharpening and are popular among professionals. Diamond stones provide durability and versatility.

When sourcing sharpening stones, consider your target market’s needs. Hobbyists might prefer affordable oil stones, while professionals may seek high-end water or diamond stones.

Use this knowledge to make informed decisions about your product lineup. Offer a mix of stone types to cater to different customer preferences and skill levels.

Ready to start your sharpening stone business? Request a free quote from NicheSources for wholesale, OEM, and private label options from China. Let’s sharpen your business edge together!