Sharpening stones are essential tools for maintaining the edge on knives, chisels, and other cutting instruments. Finding the right manufacturer can make a significant difference in the quality and performance of your sharpening stones.

Whether you’re a retailer catering to professional woodworkers, culinary enthusiasts, or DIY hobbyists, finding reliable sharpening stone manufacturers is essential for your business success.

From traditional whetstones to modern synthetic options, the choices are vast. This listicle will guide you through some of the top sharpening stone manufacturers, helping you make informed decisions for your business.

Let’s get started.

| Supplier Name | Location (Country) | Specialty | Best For |

| Shanghai Abrasive Tools Co., Ltd. (SATC) | China | Bonded & coated abrasives, OEM | Bulk OEM orders across multiple abrasive categories |

| iSharp Abrasives Tools Science Institute | China | Shaped stones, Diamond/CBN, Custom specs | Brands needing technical customization (grit, hardness, size) |

| DMT (Diamond Machining Technology) | USA | Diamond plates & tools | Premium users, professional markets |

| Naniwa Abrasive Mfg. Co., Ltd. | Japan | High-end synthetic waterstones | Chefs, enthusiasts, premium positioning |

| King | Japan (manufacturing in China) | Waterstones, combination stones | Beginner to mid-range users, kitchen & woodworking |

| Changzhou Huayida Tools Co., Ltd. | China | Diamond stones & industrial sharpeners | High-performance diamond solutions, OEM |

| Taidea Technology Co., Ltd. | China | Whetstones, diamond, sharpening systems | Brands needing a full product ecosystem |

| Zhengzhou Boson Abrasives Co., Ltd. | China | Diamond honing stones | Cost-effective diamond honing for knives/tools |

| Sharpal | USA | Diamond & ceramic handheld sharpeners | Consumer-friendly sharpeners, outdoor/sporting markets |

| Guangdong Jinhui Knife & Scissors Co., Ltd. | China | Knives + basic plastic/slot sharpeners | Knife brands wanting add-on sharpener SKUs |

How to Choose a Sharpening Stone Supplier (A Sourcing Agent’s Checklist)

When we source sharpening stones for clients, we don’t start with price or pretty catalogs, we start with the fundamentals that determine whether a product line will perform, scale, and stay consistent over thousands of units. These five checkpoints are the ones that matter the most in real-world sourcing.

1. Abrasive Material Consistency (Not Just the Material Itself)

Most buyers ask, “Is it aluminum oxide, silicon carbide, diamond, or ceramic?”

What actually matters is: How consistent is the formula from batch to batch?

Two stones can have the same advertised material but perform completely differently because:

- the abrasive grain purity varies,

- the resin/vitrified bond ratios shift,

- or the sintering temperature isn’t tightly controlled.

What we do: We request samples from two different production dates to test for cutting speed, feedback, and wear rate. If the performance varies noticeably, we don’t move forward.

This single test filters out 40–50% of suppliers.

2. Real Grit Accuracy, Not Marketing Grit

Grit numbers are easy to print on a box. What’s hard is producing stones with true, controlled particle size.

A supplier offering “1000”, “3000”, or “8000” grits isn’t impressive. A supplier who can explain whether they use JIS, FEPA, or Micron standards is.

We check:

- whether their 1000 grit feels like a true mid-grit or a disguised polishing stone,

- whether the jump between grits is logical and consistent,

- and whether their grit progression matches the needs of knife users.

Why this matters: Inconsistent grit is one of the biggest causes of bad user reviews for sharpening products.

3. Controlled Flatness & Wear Testing

Most buyers never ask this, but flatness is critical.

A stone that dishes too quickly leads to:

- customer complaints

- poor edge results

- higher return rates

We evaluate:

- initial flatness tolerance,

- how much the stone dishes after sharpening 3–5 knives,

- whether the edges crumble or stay structurally sound.

A serious supplier will:

- measure flatness during QC,

- offer optional lapping/flattening plates,

- and publish wear data.

This separates hobby-tier factories from professional-grade suppliers.

4. OEM/ODM Capability That Actually Scales

Customization isn’t just about printing your logo.

A good sharpening stone supplier should support:

- unique grit pairings (e.g., 800/3000, 1000/6000, 1500/5000),

- custom hardness levels depending on knife steel,

- packaging design that fits your brand’s positioning,

- auto-generated barcodes/packaging specs,

- small first-run MOQs for new SKUs.

Most “OEM” claims on Alibaba are superficial. We only work with suppliers who let you shape the product, not just the box.

5. Transparent QC Workflow and Corrective Process

This is the part many suppliers try to gloss over.

A serious sharpening stone manufacturer will:

- share their QC checklist (flatness, hardness, moisture content, bond density)

- document how often they recalibrate their equipment

- provide a path for handling defect rates

- explain how they test each grit level for accuracy

Why this matters: Sharpening stones are performance products. If QC isn’t documented, you will eventually face inconsistent batches, bad reviews, and costly returns.

A supplier that can clearly walk you through their QC workflow is a supplier you can scale with.

A List of Sharpening Stone Manufacturers

When selecting a manufacturer, consider factors such as stone material, grit size, and intended use. This will help you find the perfect sharpening stone for your tools.

Remember to check product reviews and compare prices before making your final decision. Many of these manufacturers offer both retail and wholesale options, so you can choose the best purchasing method for your business needs.

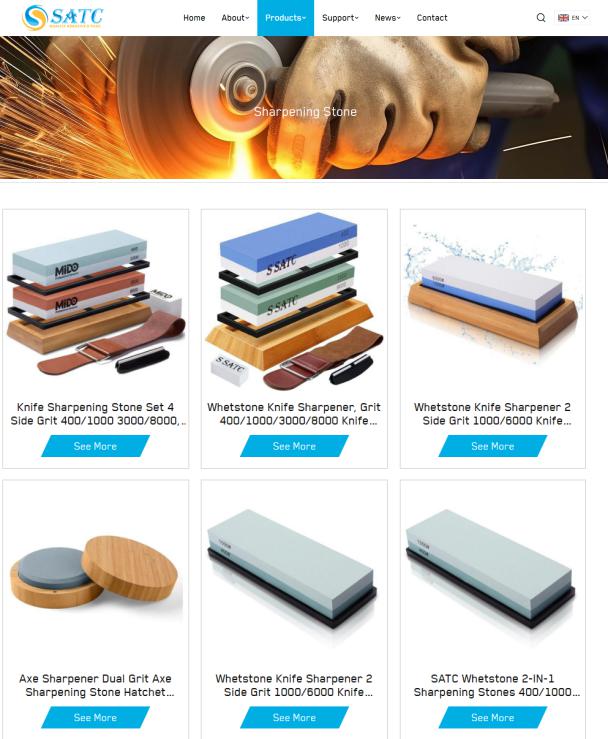

Shanghai Abrasive Tools Co., Ltd. (SATC)

Our assessment is that Shanghai Abrasive Tools Co., Ltd. (SATC) is a dependable choice for buyers looking for a wide range of abrasive solutions. The company has been operating since 1990, and over the years we’ve found that their strength lies in producing consistent, reliable cutting, grinding, and polishing tools. Their bonded and coated abrasives are well-developed, and their knife sharpeners deliver solid performance for everyday use.

SATC’s product line is broad, which makes them suitable for brands sourcing multiple abrasive categories from a single supplier. Their experience and certification standards also give us confidence in long-term cooperation.

Key Information

- Location: Shanghai, China

- Main Products: Knife sharpeners, Cutting and grinding wheels, flap discs, abrasive papers and sanding belts

- Export Focus: North Europe, West Europe, and North America

- Certifications: MPA, ISO, and BV certificates

- Sample Availability: Free samples are available for quality testing, but customers are responsible for shipping costs.

- Customization Options: ODM services are offered for customer brands. The company can print your brand on the liner, packaging sleeve, and box.

Strength

- Over 30 years of experience in the abrasive tools market

- Wide range of abrasive products, including specialized knife sharpeners

- Dedicated research team of experienced abrasive engineers

iSharp Abrasives Tools Science Institute

Our assessment is that iSharp is a dependable option for buyers who need a wide variety of shaped and specialty sharpening stones.

Since 1991, they’ve focused heavily on engineering different abrasive materials, which shows in the consistency of their diamond, CBN, and ceramic fiber stones.

Their ability to customize size, grit, and hardness makes them suitable for brands that need more technical or application-specific sharpening tools.

Key Information

- Location: China

- Main Products: Various shaped stones: Square, triangular, semi-circular, round; Specialized stones: Diamond honing stones, CBN stones, ceramic fiber stones, oil stone

- Certification: ISO 9001: 2008

- Customization Services: Customizable sizes, grits, and hardness levels to meet specific requirements

Strengths

- Extensive experience in the abrasive tools industry since 1991

- Helps users improve grinding efficiency and quality while reducing costs

- Dedicated research team of experienced abrasive engineers

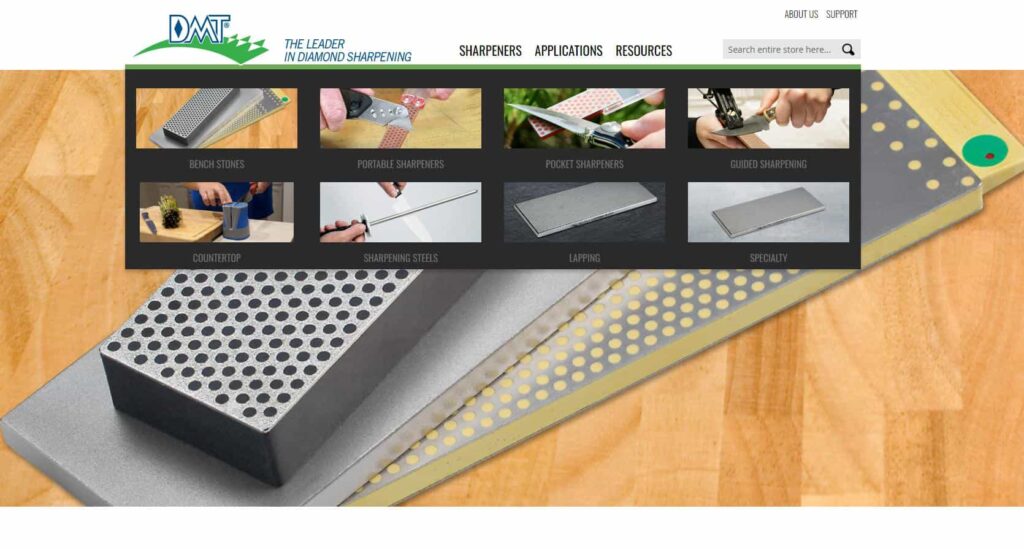

DMT (Diamond Machining Technology)

From our experience with diamond sharpening tools, DMT remains one of the most reliable names in the category.

They pioneered many of the diamond-plate technologies still used today, and their tools are known for both durability and aggressive cutting action.

For brands serving professional or premium audiences, DMT offers consistently high performance, though at a higher price point than traditional stones.

Key Information

- Location: USA

- Main Products: Diamond sharpening stones and tools

- Target Industries: Woodworking, DIY, culinary, outdoor sports, winter sports, and landscaping

- Quality: Known for high-quality diamond abrasives that provide effective sharpening

Strengths

- Long-standing expertise in diamond sharpening technology (since 1976)

- Wide range of diamond sharpening solutions for different industries

- Very durable diamond sharpening tools

- Aggressive cutting performance that saves time

Cons

- Higher price point compared to traditional sharpening stones

Naniwa Abrasive Mfg. Co., Ltd.

In our view, Naniwa is one of the top Japanese manufacturers for premium waterstones.

With a history dating back to 1954, they’ve refined their synthetic stone formulas to deliver smooth feedback, fast cutting, and consistent grit control.

Their Chocera and Professional lines, in particular, are highly regarded among chefs and knife enthusiasts who prioritize precision and edge quality.

Key Information

- Location: Osaka, Japan (with additional manufacturing facilities in China)

- Established: 1954

- Main Products: Premium synthetic waterstones, particularly in the Chocera and Professional lines

- Target Audience: Professional chefs, knife enthusiasts, and high-end users

- Quality: Known for exceptional cutting performance, consistent grit sizes, and a luxurious feel during use

Strength

- Over 65 years of experience in sharpening stone technology

- Excellent feedback during sharpening process

- Wide range of grit options available

- Popular among professionals

- Ability to provide a fine edge and quick cutting capabilities

Cons

- Higher price point compared to some alternatives

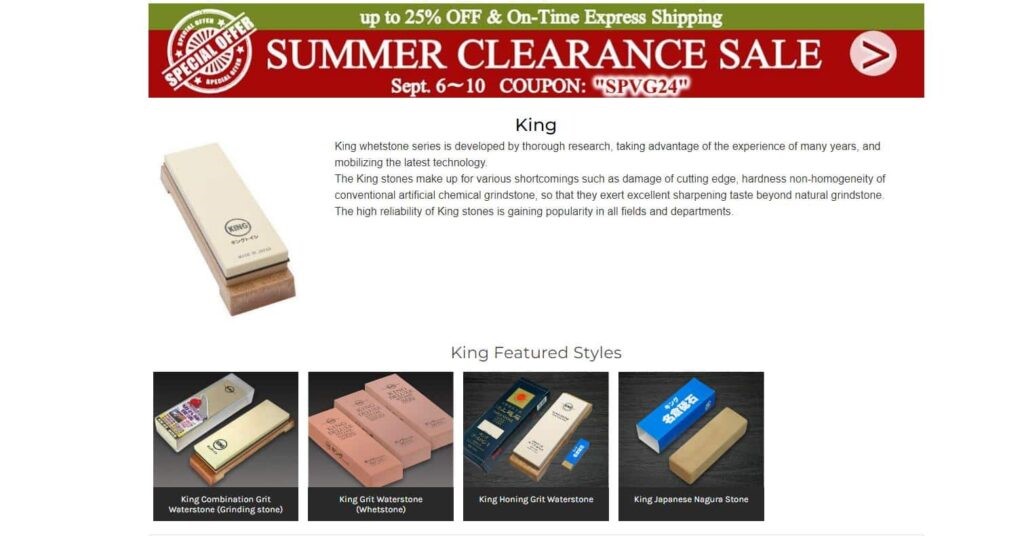

King

Our assessment is that King remains one of the most accessible and trusted names in Japanese waterstones.

With a history dating back to 1908, they offer a reliable sharpening experience at a very approachable price point.

Their stones are softer than many modern synthetics, which gives them a smooth, comfortable feel during use, something both beginners and experienced sharpeners appreciate.

Key Information

- Location: Japanese company with manufacturing facilities in China

- Main Products: Waterstones, including popular combination stones with multiple grit levels

- Target Audience: Chefs, home cooks, woodworkers, and general users

- Quality: Softer stones that offer pleasant feedback and strong cutting performance

Strengths

- Over 100 years of experience in whetstone manufacturing

- Soft composition makes sharpening easy and forgiving

- Well-regarded by both new and experienced users

Cons

- Softer stones wear faster and require regular flattening

- Some users may find the extra maintenance inconvenient

Changzhou Huayida Tools Co., Ltd.

In our experience, Changzhou Huayida is a solid choice for buyers specifically looking for diamond sharpening solutions.

Since 2005, they’ve focused almost entirely on diamond-based tools, which results in consistent hardness, fast cutting, and long product life.

Their catalog works well for brands targeting professional or industrial users who need reliable performance.

Key Information

- Location: Changzhou, Jiangsu Province, China

- Main Products: Diamond bench stones, double-sided diamond stones, knife sharpeners, files, and related tools

- Service: OEM/ODM services with custom branding

- Certification: ISO 9001

Strengths

- Strong specialization in diamond sharpening technology

- Suitable for professional, industrial, and high-performance use

- Good balance of durability and cutting speed

- Effective for a wide range of knives and tools

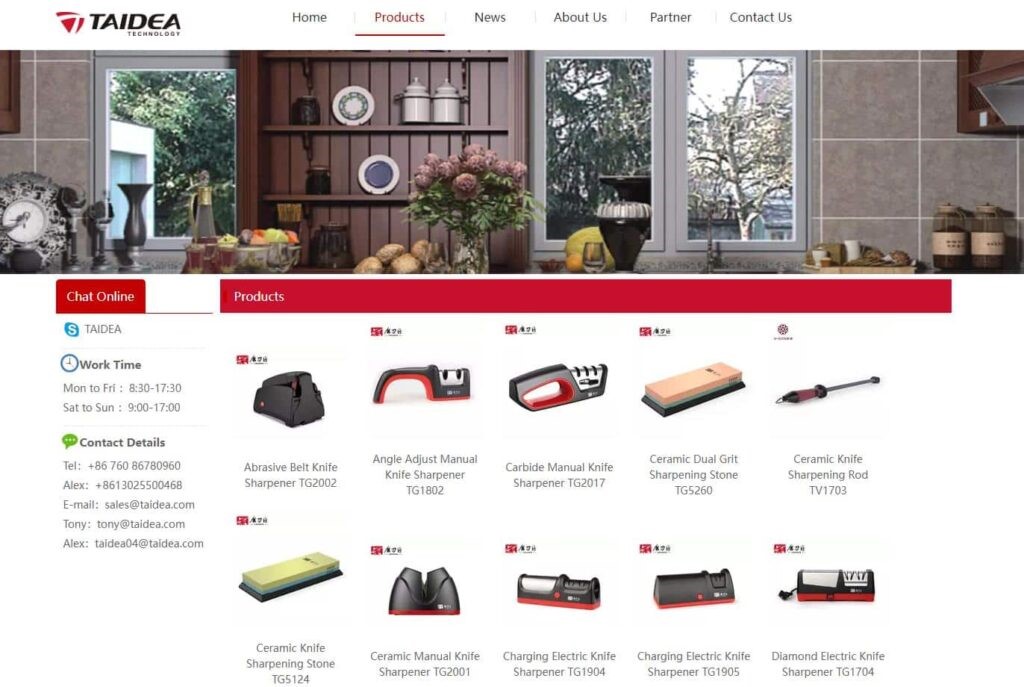

Taidea Technology Co., Ltd.

Our assessment is that Taidea offers one of the more versatile product ranges among Chinese sharpening tool manufacturers.

Since 2006, they’ve built a catalog that includes waterstones, diamond stones, and complete sharpening systems, making them suitable for brands wanting multiple formats under one supplier.

Their quality testing and three-year guarantee also give buyers additional confidence.

Key Information

- Location: Yangjiang, Guangdong Province, China

- Main Products: Whetstones, diamond sharpeners, and full sharpening systems

- Services: Sample customization, product design services

- Certifications: ISO 9001, ISO 14001, BSCI

- Quality: Products tested for durability and sharpening performance; 3-year quality guarantee

Strengths

- Innovative designs that address different sharpening needs

- Strong customer focus with reliable quality control

- Active R&D efforts for improved sharpening technology

Zhengzhou Boson Abrasives Co., Ltd.

Our assessment is that Zhengzhou Boson is a dependable supplier for buyers who need a focused range of diamond honing and sharpening stones.

Since 2005, they’ve built a solid portfolio of single-pass honing tools and abrasive products that work well for both professional workshops and home use.

Their production timelines are reasonable, and their ISO certification adds a layer of reliability for long-term sourcing.

Key Information

- Location: Zhengzhou, Henan Province, China

- Main Products: Honing stones, diamond honing stones, single-pass honing tools, related abrasive items

- Certification: ISO 9001

- Production Timelines: 15–30 days

Strengths

- Wide product selection for different sharpening applications

- Competitive pricing with flexible order quantities

Sharpal brings 20+ years of experience to the sharpening tools market, and in our view, they excel at designing user-friendly solutions for everyday knife and tool maintenance.

Their catalog includes diamond and ceramic sharpeners, sharpening rods, and several patented designs that set them apart in the consumer market.

Key Information

- Location: USA

- Main Products: Diamond sharpeners, ceramic sharpeners, sharpening rods

- Target Audience: Professional users and home consumers

Strengths

- Practical, easy-to-use designs

- Broad selection of sharpeners for different tasks

- Strong focus on user experience, including demo videos

- Unique product innovations such as BuddyGuard and diamond lapping plates

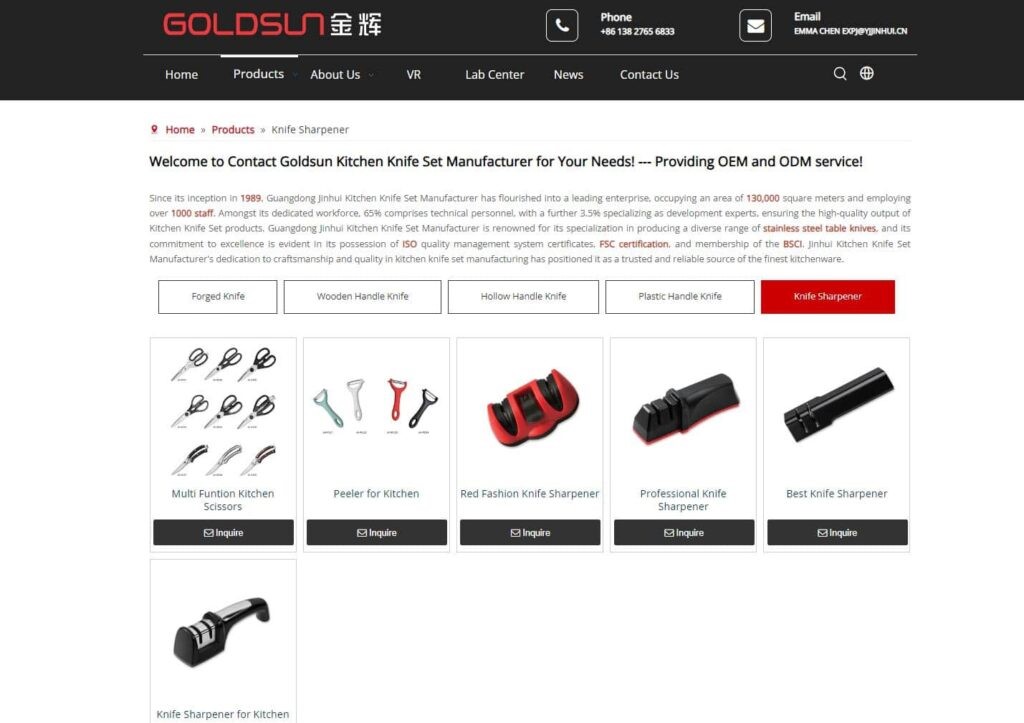

Guangdong Jinhui Knife and Scissors Incorporated Company Ltd.

Our assessment is that Guangdong Jinhui is a well-established manufacturer with strong capabilities in stainless steel knives and cutting tools.

While sharpeners are not their primary product line, they do offer a range of basic two-slot sharpeners that complement their core catalog.

Their scale, certifications, and sustainability initiatives make them a reliable partner for larger volume orders.

Key Information

- Location: Guangdong Province, China

- Main Products: Stainless steel table knives, cutting tools, and simple knife sharpeners

- Service: OEM and ODM

- Certifications: ISO 9001:2008, FSC, BSCI

- Shipping: USA, Europe, Southeast Asia, Middle East

Strengths

- Established reputation with large-scale production capability

- Over 1,000 machines and a skilled technical workforce

- Strong engineering and development resources

- Sustainability focus, including solar panel installations

Cons

- Knife sharpeners are secondary to their main product offerings

Frequently Asked Questions

What Type of Sharpening Stone Is Best?

The best sharpening stone depends on your specific needs. Water stones are popular for their versatility and ease of use. Oil stones offer durability and are great for maintaining a sharp edge.

Diamond stones provide fast sharpening and work well for hard steels. Ceramic stones offer a balance between speed and precision.

What Are Japanese Whetstones Made Of?

Japanese whetstones are typically made from natural or synthetic materials. Natural stones often contain silica and other minerals. Synthetic stones are made from aluminum oxide or silicon carbide abrasives.

These materials are bonded together to create a porous structure. The porosity allows the stone to wear away during use, revealing fresh abrasive particles.

What Is the Manufacturing Process of Whetstone?

The manufacturing process of whetstones varies depending on the type. For synthetic stones, abrasive particles are mixed with a bonding agent. This mixture is then molded and fired in a kiln.

Natural stones are quarried and cut to size. They may undergo additional processing to ensure consistent quality.

Which Countries Are the Main Manufacturers of Sharpening Stone, and How Do They Compare?

Japan is renowned for high-quality sharpening stones, especially natural whetstones. The United States produces a wide range of synthetic stones. China is a major manufacturer of affordable synthetic stones.

European countries like Germany and Austria also produce high-quality sharpening stones. Each country has its strengths in terms of quality, price, and variety.

Learn more about the benefits of sourcing high-quality sharpening stones wholesale directly from China here.

How Do I Find a Good Sharpening Stone Supplier in China?

To find a good supplier in China, start by researching online marketplaces and trade websites. Look for suppliers with positive reviews and a history of international trade.

Request samples to test quality. Verify the supplier’s certifications and manufacturing capabilities. Consider working with a sourcing agent for added security.

What should one consider when choosing a manufacturer for sharpening stones?

Consider the manufacturer’s expertise and years in the industry. Look at their product range and ability to provide stones for different applications.

Evaluate their production capacity, lead times, and minimum order quantities. Check if they offer customization options and after-sales support.

Summing Up: Find the Right Supplier for Your Next Best-seller

Choosing the right sharpening stone manufacturer is crucial for your business success. You’ve learned about various options, from traditional natural stones to modern synthetic materials.

Remember, quality and consistency are key factors to consider. Look for manufacturers with a proven track record and positive customer feedback.

Don’t forget to match stone sizes to your product range. Smaller stones work well for pocket knives, while larger ones are ideal for kitchen knives.

Consider your target market’s needs. Some customers prefer the authenticity of natural stones, while others value the precision of synthetic options.

Pricing and shipping capabilities are also important factors. Ensure your chosen manufacturer can meet your volume requirements and delivery expectations.

Ready to take the next step? Get a quote for sourcing sharpening stones tailored to your specific needs. With the right manufacturer, you’ll be well-equipped to offer top-quality sharpening solutions to your customers.