Every business is eager to increase sales while maintaining a large inventory. A good business ensures that its products are liquidated regularly even at a lower return on investment.

That is why the idea of kitting came into being to sell a variety of items by grouping them together. In this guide, you will learn what kitting is, how it is done, and what benefits you can get by selling products in kits.

At the end of this article, you will be in a better position to understand kitting meaning and the necessary information revolving around this concept.

Let’s start.

What Is Kitting?

Kitting is the act of combining a set of products in one place to turn them into a single kit.

These products may be meant for the same purpose or destination. A kit may also come under a sale package to boost sales of different items.

A good example of kitting in our daily lives is a shaving kit which is a single package containing different items related to shaving. It may include a shaving razor, shaving foam, aftershave lotion, etc.

Another example can be a beauty kit.

The concept of kitting applies to a vast array of activities. Let’s discuss them in detail.

Some common examples of kitting in our daily lives include the following.

- First-aid kit

- Toolbox kit

- Car kit

What Is the Kitting Process?

The kitting process involves the following 5 simple steps.

1. Receive a Kitting Requirement

The kitting process starts when a requirement for a set of products arises. This requirement can come directly from the end-user (pull sale) or the seller (push sale).

When a warehouse or any other facility that holds multiple products receives a requirement for related products, they initiate the kitting process.

Note: The warehouse staff may also start the kitting process automatically by organizing or kitting the items as per their color, size, or nature to optimize the inventory storage.

2. Locating and Picking the Items for Kitting

After receiving the requirement, the staff will start locating the products that need to be in the kits. They mostly take help from their systems or storage labels to locate and pick the items.

3. Combining and Packing the Kitting Items

After they pick the items, they start combining them in one place to make kits. They inspect and validate the items as per the requirements.

They pack the items together according to the instructions and turn them into kits.

4. Labeling the Kits

After making the kits as per the requirements, the staff labels them as individual SKUs that are ready to leave the warehouse.

The kit will then be treated as a single entity and will bear a single scannable SKU number. The label or barcode may show the product details inside the kit when it is scanned.

These labeled kits may be placed separately that are ready to leave the warehouse as per the shipment plan.

5. Shipping the Kits

These kits will then be dispatched from the warehouse to their destination as individual pieces or in groups. The records of the warehouse will be updated accordingly.

Assembly and packaging are the two crucial steps in the process of kitting. Let’s discuss them in detail.

Kitting and Assembly

Assembling is the process of putting two or more items together in one place. In most cases, assembling precedes the packaging stage in the kitting process.

If the items are placed at different locations at a storage place, the staff would pick the items and assemble them to make them a single kit.

Assembling can be a manual or an automated process requiring conveyor belts.

The practice of assembling is more organized at larger warehouses. The storage places where a large number of products are to be assembled install assembly lines to optimize the assembling process.

There is a dedicated staff who combines the items one by one to make the items fully assembled at the end of the assembly line.

The assembled products are then moved towards the packaging and labeling stages of kitting.

Kitting and Packaging

Packaging is the final stage of the kitting process. It is the packaging that turns a set of items into a kit.

Packaging is often considered the most crucial stage in the kitting process while preparing the orders for a private label business.

The packaging bears the logo or the brand name of the private label business so that the end-user knows where the products came from.

In a more systematic private label or white label business, each item inside the kits also needs to be labeled with the brand name.

That’s why packaging needs special care and attention from the packaging staff.

In addition to the labeling, the packaging ensures that the items inside the kits are safe to travel. A wrong or substandard packaging may result in the loss or damage of goods during transit.

Following are the most common types of packaging used in the kitting process.

Boxes

Boxes are widely used to pack small-sized items. Warehouses have boxes of different sizes and materials so that they can pack the items as per their sizes and dimensions.

An appropriate box is selected to accommodate all the items and pack the products safely.

It is also convenient for the packing staff to label the boxes and put scannable SKUs along with any handling instructions if applicable.

The most common boxes are made of corrugated paper or plastic, etc.

Wrapping

Wrapping refers to covering a group of items with a protective sheet so that it forms a single kit. Most common wrapping practices include shrink wrapping and bubble wrapping, etc.

Bags

Some items are also packed in bags. Bags are relatively low-cost packing solutions. Examples of bags include poly bags and paper bags, etc.

Cases

A case refers to the type of packaging where two or more products are combined in the form of sets. You would have noticed a case of beverage cans packed as a single unit.

A case generally has predefined sections meant to place the items inside those spaces to keep them intact.

Pallets

A pallet is meant to combine a larger number of items into one entity. This allows storing and moving those items as a single pallet containing multiple items.

The items in the pallets are also stacked upon each other in a way that one product does not damage the other.

Kitting Meaning in Warehouse

The process of kitting in a warehouse refers to sorting, arranging, and combining different items or SKUs to turn them into a new single SKU.

It is done to make warehouse inventory management more efficient. It helps warehouse staff locate, organize, and process the inventory more efficiently.

It also reduces the chances of errors while warehouse staff handles inventory.

As the products are being dispatched to end-users from a warehouse, kitting helps staff to pick, pack, and dispatch the orders on time.

Rather than finding individual products and processing them one by one, they pick up a single kit and send it to the destination as one unit.

Kitting Meaning in Logistics

Kitting plays a vital role in the supply chain process. The process of kitting in logistics starts right from where the shipment is loaded from the destination and continues till the individual packages are delivered to the end-users.

The products are organized and packed as per their destination in form of kits. They are loaded onto the container meant to head towards the destination.

While the container may have items that are supposed to be delivered at different locations of the destination place, they are all headed towards a single country, city, or town.

The following scenario may explain the kitting process in international logistics.

Suppose there are a lot of products that are ordered by different customers in the USA from China. These orders may come from different states of the USA.

The logistics company will have the products from Chinese suppliers along with all the delivery details of the orders.

Now, the logistics company will apply the kitting concept to optimize their delivery process to minimize the costs of delivery while keeping the delivery time as short as possible.

Depending upon the order details, they may combine the orders that are meant to be delivered at a certain port in the USA.

Let’s say that they have a full container load of orders that are supposed to be delivered at the port of Los Angeles.

The logistics company will combine all the orders to be shipped to LA in a single container and will dispatch accordingly. This will optimize their time and cost to deliver this shipment.

The kitting in logistics will have its second phase when the container reaches and off-loads at the LA port.

The logistics company in LA will open the container and will start organizing products as per their destinations in different cities surrounding LA.

Other activities that are generally performed alongside kitting are counting, inspection, and verification of the products to be delivered.

The logistics company will deliver the products one by one to the end-users in a systematic way that minimizes their time, costs, and efforts in the whole process.

Kitting Meaning in Manufacturing

Kitting in manufacturing means either assembling the raw materials required at the manufacturing line or the finished goods meant to be transported at some other point.

In the first case, a manufacturing line may require different kinds of raw materials at different points.

A line supervisor may bundle the most demanded raw materials together and place them beside the manufacturing spot that requires them.

This increases the manufacturing efficiency and reduces time and fatigue to bring different raw materials one by one.

In the second case at manufacturers, the manufacturer may bundle the finished goods together to easily dispatch them to the next manufacturing line or the warehouse.

Kitting Meaning in eCommerce

Kitting in eCommerce means promoting and selling multiple items as single sets via an online shopping platform.

Promoting products in kits entices a potential shopper to even buy things he might not have bought independently.

Let’s discuss a typical kitting example in eCommerce.

Suppose you have visited an online store to buy a charger and a hands-free for your mobile phone.

A good kitting offer may tempt you to buy the complete kit of accessories for your phone that contains screen protectors and back covers in addition to the charger and the hands-free.

The kit may cost you a few bucks more than the price of hands-free and a charger. The thought of getting the whole package at discounted price compels the customer to buy the whole kit.

This technique liquidates the dead items of eCommerce stores and also increases their sales to manifolds.

Types of Product Kitting in eCommerce

The following are the most common types of product kitting in eCommerce. Let’s discuss them briefly.

Frequently Bought Together

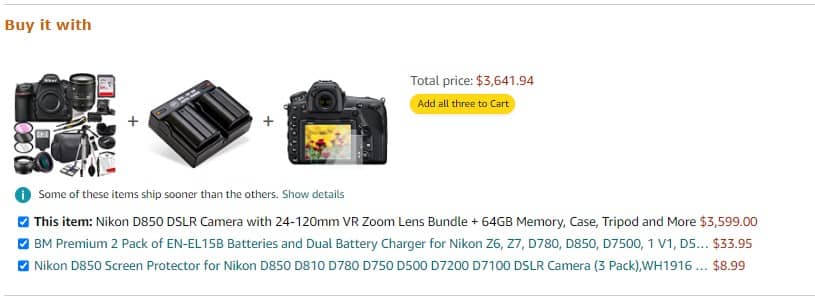

Another technique to increase the sale of related items is “frequently bought together”. When you visit a product page on the online store, it mentions that other customers are buying the mentioned products along with the products you are interested in.

This also induces the urge to buy those additional items along with the items you actually want.

This is one of the most popular kitting strategies in eCommerce. E-commerce giants like Amazon also use this technique. They also term it “Buy it with”.

Sometimes, this technique also makes the customers realize that they were also in need of those extra products.

In this case, also, the online seller has already informed its order fulfillment centers to combine “frequently bought together” products and sell them as a kit after a customer places orders for those products.

This kitting type is also known as cross-selling or upselling.

Gift Box

Some online stores often run a promotion on their items while showing that the items inside the gift boxes are on sale. This is to tempt their visitors to buy those gift boxes without thinking much.

Normally, a countdown timer is running to induce a sense of urgency among their visitors to buy before the promotion is over.

These gift boxes are the most common examples of product kitting in eCommerce.

The suppliers or the store owners have already instructed fulfillment centers to combine the products in gift boxes and sell them as single units when the customer places an order for these boxes.

Subscription Box

As the name suggests, a subscription box refers to a customer’s monthly subscription for certain items. These are the items that the customer has asked an online shop to deliver every month.

As these are the repeat orders from predefined customers, the products are combined in kits and sent as single units to the customers regularly.

These subscription boxes are also pre-assembled at fulfillment centers so that they can be dispatched on the decided date every month.

Mystery Box

Promoting a mystery box is also a good technique for selling product kits. In this strategy, the online store offers a set of undisclosed products in a box.

A store may also show some of the items inside the box to convince a customer that the mystery box would be worth buying.

These mystery boxes are also prepared in advance at the fulfillment centers and are ready to be shipped after receiving an order.

Pre-assembled Kits

Some products are promoted as final products on the online stores but they are stored in parts at the warehouses.

When they receive the order for a final product, they start assembling the parts to make the final product.

Kitting Meaning in eCommerce Fulfillment Centers

Kitting is probably most relevant at fulfillment centers. As there are a lot of small orders in eCommerce, unplanned storage and shipping of individual parcels would skyrocket the overall costs.

That’s why fulfillment centers try to make the best use of kitting options.

Following are a few scenarios of kitting in eCommerce fulfillment centers.

Storage Kitting

A fulfillment center may want to improve its efficiency by putting similar products side by side to shorten the fulfillment time.

As they have to pick, assemble, pack, and ship a lot of orders daily, they have developed a sense to store the related products together.

The staff can also organize the items as per their size, type, and fragility to keep them safe and easily accessible.

In this way, some fulfillment centers make storage kits to ease out their operations.

Group Shipment

Group shipment refers to the shipment of multiple products in one group to the same customer. This is to save the extra shipping costs that would have been incurred if the products were dispatched individually.

If you order regularly from Amazon, you would have noticed that you get your multiple orders together that you actually placed individually.

In this case, Amazon notices that it needs to deliver different items to one customer. They pick all the items and ship them in a single group to the customer’s address.

Note: For a group shipment to be possible, all the items must be available at the same fulfillment center.

Pros and Cons of Kitting in E-commerce

Kitting in eCommerce has a lot of benefits with a few potential risks. Let’s discuss them briefly.

Pros of Kitting

Following are the benefits of kitting in eCommerce.

- More high-value orders

- Liquidation of less ordered products

- Efficient utilization of storage space

- Reduced product supervision

- Lower staff administration at warehouses

- Lower shipment costs

- Fast delivery and reduced lead time

- Fewer packaging and shipping errors

Cons of Kitting

While kitting has a lot of benefits, it may pose only a few potential risks that are listed below.

- In case of loss or damage, the whole kit along with all the products inside a kit will get affected.

- The hot-selling items in pre-made kits will also remain on hold until the orders for kits are received.

How to Manage Kitting?

There is a simple drill you need to follow while managing the kitting process. The tips are briefly mentioned below.

- Document the kitting requirements to establish what products to be kitted.

- Prioritize the kitting requirements as per your orders.

- Give clear instructions to the kitting staff about storing and packaging the kitting products.

- Use appropriate packaging to avoid extra charges for dimensional weight.

- Assign a designated area in the warehouse for kitting products to avoid mixing with storage kitting.

- Assign correct SKU numbers for kits to identify and track them easily.

- Supervise the kitting process yourself or deploy an expert to ensure minimal errors.

3PL Kitting Services

3PL kitting services refer to the services rendered by third-party logistics on behalf of other businesses.

Most eCommerce businesses don’t own their fulfillment centers but they have to get their products fulfilled in kitting or non-kitting forms. That’s where the 3PL services pop in.

A good 3PL service provider like Niche will make kitting easier for you in the fulfillment process. It will store your inventory, assemble, and make kits as per your instructions.

Our dedicated warehouse staff in China and the USA are well trained to provide professional kitting services.

FAQs about Kitting

The following answers are the most frequently asked questions about kitting which will help you understand it better.

How Is Product Kitting Different from Product Bundling?

Product kitting is the act of combining products into single kits while product bundling refers to making bundles of different or similar products.

Product bundling may be done before making a final kit. Unlike kits, bundles may not have individual SKU numbers.

What Is the Difference Between Material Kitting and Product Kitting?

Material kitting is the terminology mostly used in manufacturing. It hints at making kits of raw materials to be placed in the manufacturing area.

It is called material kitting at manufacturing facilities and product kitting at fulfillment centers or warehouses.

What Is a Kitting Position?

A kitting position refers to the point where all the products or materials are brought to be combined into one kit.

It may be a dedicated space at a warehouse, an area near a manufacturing line, or a place near a loading facility in logistics.

Final Verdict

The kitting concept applies to our personal and professional lives to make the efficient utilization of space and usage. It is an important tool to boost sales along with streamlining your inventory.

The benefits of kitting highly outweigh its potential risks. So, as a business owner, you would not want to miss this highly useful selling and product handling tactic.

If you want to source and sell a variety of your products in kits, you would need a reliable 3PL kitting service as we offer at Niche. Ask for a free quote today and one of our sourcing and kitting experts will assist you through every step.