LEGO is one of the most popular toy brands in the world, but where are all those tiny bricks actually made?

While the company started in Denmark, LEGO now runs factories in several countries across Europe, Asia, and North America.

In this article, we’ll take a closer look at where LEGO toys are made today, how they’re manufactured, what materials go into them, and why they can be so expensive.

If you’re a seller or sourcing professional, you’ll also find useful tips on what to learn from LEGO’s global production strategy.

Quick History of LEGO Production

- 1932 – LEGO was founded by Ole Kirk Christiansen in Billund, Denmark (the LEGO House), originally producing wooden toys.

- 1949 – The company began producing plastic “Automatic Binding Bricks,” the early version of LEGO bricks.

- 1958 – The iconic LEGO brick design with the interlocking stud-and-tube system was patented. This is still the foundation of every LEGO piece today.

- 1960s–1980s – LEGO rapidly expanded across Europe and North America, with increasing demand pushing production beyond Denmark.

- 2000 – As LEGO became a global brand, the company began diversifying its manufacturing footprint to stay closer to regional markets.

- 2013 – LEGO opened a high-tech factory in Nyíregyháza, Hungary, consolidating multiple European facilities.

- 2016 – The Jiaxing, China factory began operations, marking LEGO’s first large-scale plant in Asia.

- 2022 – LEGO announced a $1B+ investment in a new carbon-neutral factory in Vietnam, set to open by late 2025.

Where Are LEGO Toys Manufactured Today?

Although LEGO began in Billund, Denmark, its production network has expanded worldwide to keep up with global demand.

Today, LEGO bricks are manufactured in several key locations:

- Denmark (Billund)

- Czech Republic

- Hungary

- Mexico

- China

- Vietnam (factory expected to launch by late 2025)

Billund still plays a central role, producing over 20 billion bricks annually, but newer facilities support regional markets more efficiently.

The Czech Republic and Hungary focus on European distribution, Mexico serves the Americas, and China supplies the fast-growing Asian market.

A new LEGO factory in Vietnam is currently under development to boost capacity and support sustainability goals in the region.

Are Legos Made in China?

Yes, but not in the way you might think. LEGO does have a factory in Jiaxing, China, which opened in 2016.

It was built to serve growing demand in Asia and is fully owned and operated by LEGO, not a third-party supplier. That’s important because it means the factory follows the same quality standards and processes as LEGO’s European or North American sites.

The Jiaxing facility handles molding, decoration, and packing, primarily for the Asia-Pacific market. It’s part of LEGO’s “produce where we sell” strategy, minimizing shipping costs, reducing emissions, and keeping regional supply chains efficient.

Fun fact: Many people assume LEGO made in China means lower quality — but the Jiaxing factory uses the same precision molds (down to 0.002mm tolerances) and ABS material as any other LEGO facility.

That said, not all LEGO sets are made in China. If you’re buying in the U.S. or Europe, your bricks likely come from factories in Mexico, Hungary, or the Czech Republic.

So yes, some LEGOs are made in China, but it’s part of a tightly controlled, high-standard global operation.

Role of LEGO’s Global Manufacturing Network

LEGO’s “globally local” approach means they build factories close to their biggest markets, helping reduce lead times, lower emissions, and meet local demand faster. Each facility plays a unique role in the overall production ecosystem:

- Billund, Denmark: The original home of LEGO, this site now focuses on specialty molding and pilot production for new bricks and designs.

- Nyíregyháza, Hungary: A key manufacturing hub serving Europe. It handles molding, decoration, and packaging for a wide range of sets.

- Kladno, Czech Republic: Specializes in decoration and packaging, including custom kits and promotional packaging.

- Monterrey, Mexico: Supplies the U.S., Canada, and Latin America. It’s one of LEGO’s largest factories, helping speed up delivery across North America.

- Jiaxing, China: As mentioned earlier, this factory supports the Asia-Pacific market with molding, printing, and packing, built with the same tech and quality standards as LEGO’s European sites.

- Vietnam (upcoming): LEGO’s new carbon-neutral factory in Binh Duong Province is set to open in late 2025. It’s designed to meet Asia’s growing demand and run entirely on solar energy.

How Are LEGOS Made?

LEGO bricks may look simple, but the process behind them is anything but.

Here’s a quick breakdown of how LEGO turns raw plastic into some of the most precise toys in the world:

1. Raw Material: ABS Plastic

Most LEGO bricks are made from Acrylonitrile Butadiene Styrene (ABS), a durable, heat-resistant plastic known for its strength and glossy finish.

ABS is ideal for toys because it holds its shape, doesn’t crack easily, and retains color over decades.

LEGO uses high-purity ABS granules sourced from approved suppliers (more on that at the end of this chapter). The granules are fed into hoppers at the factory.

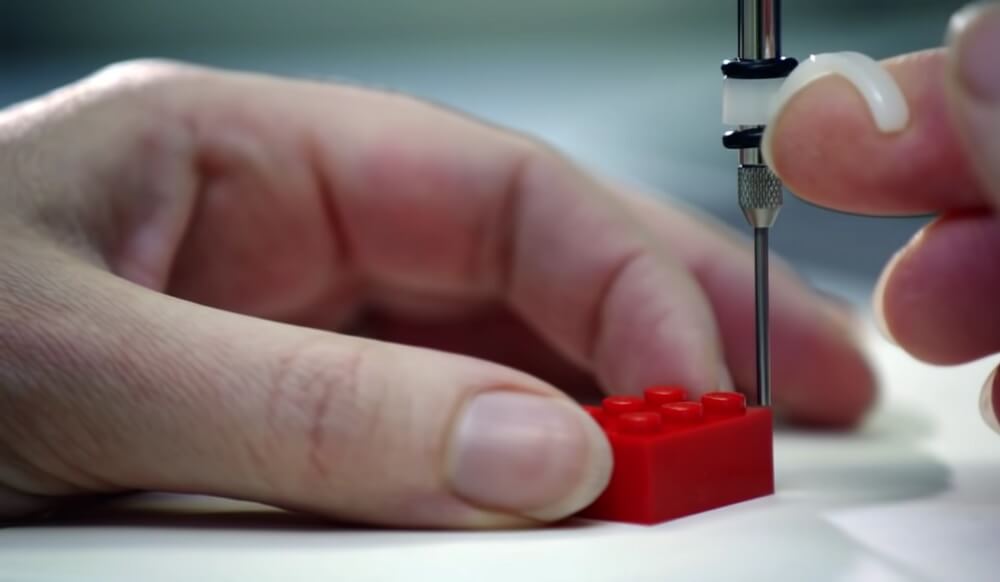

2. Injection Molding

The granules are heated to around 230°C and injected into precision molds, some of the most advanced in the toy industry.

Each mold is engineered with 0.002 mm accuracy, ensuring every brick fits perfectly with another, no matter when or where it was made.

LEGO owns over 9,000 different mold types, from simple 2×4 bricks to specialty parts.

3. Cooling and Ejection

After injection, the molds are cooled for a few seconds. Once solidified, the bricks are automatically ejected and moved to quality checks. Any defective pieces, even if just slightly warped, are ground down and recycled internally.

4. Decoration and Printing

Printed bricks (like faces or dashboard panels) go through a separate decoration process using pad printing, not stickers. This ensures long-lasting, smudge-resistant detail.

5. Quality Control

LEGO is famous for its quality, and for good reason. Every brick batch goes through rigorous automated inspections, with some factories even using X-ray scanners to check internal structure.

6. Packaging

Finally, the correct pieces are counted, bagged, and boxed into kits, ready to ship to stores or warehouses around the world.

If you’re curious about where LEGO gets its materials from, the company publishes an official list of approved partners. These LEGO raw material suppliers are carefully audited to ensure consistency, safety, and ethical sourcing.

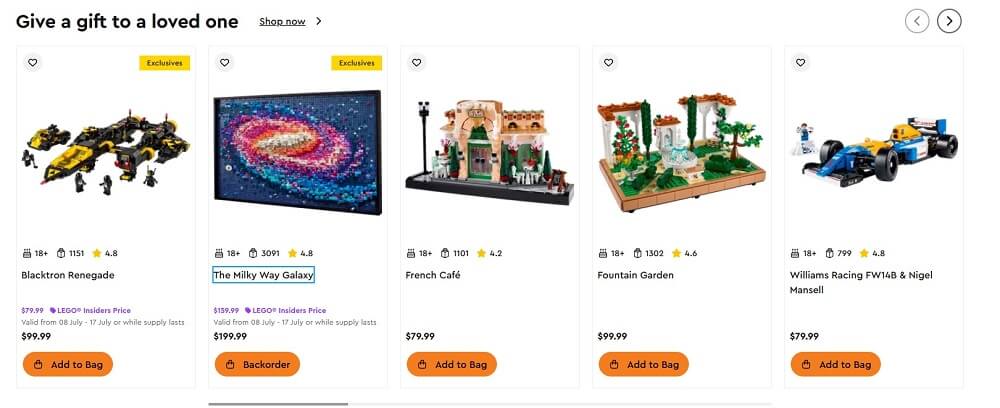

Why Are LEGOs So Expensive?

It’s a common question, why do LEGO sets cost so much compared to other building toys? The answer lies in a mix of precision engineering, premium materials, licensing costs, and brand trust. But let’s break it down.

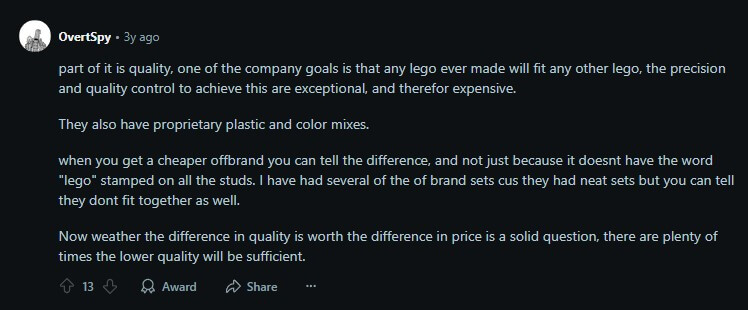

What People Are Saying

On Reddit and Quora, buyers often mention:

- Unmatched quality and precision. LEGO bricks have near-perfect consistency, even pieces from decades ago still fit today.

- Brand perception. LEGO is seen as a premium, long-lasting toy. Many users are willing to pay more for durability, resale value, and collector appeal.

- Licensing costs. Sets based on Star Wars, Harry Potter, Marvel, etc., include hefty licensing fees, which are passed on to consumers.

One Redditor put it simply:

What It Means from a Sourcing Perspective

- LEGO uses high-purity ABS plastic, not cheap fillers. This material is more expensive, but it delivers unmatched strength and color longevity.

- The company invests heavily in mold engineering, with tolerances as tight as 0.002mm, far more precise than most toy factories.

- LEGO runs automated quality checks at every step, reducing defect rates and increasing costs.

- Sustainable initiatives (like sugarcane-based bioplastics and carbon-neutral factories) add to production costs but align with long-term brand values.

What to Look for in a Building Brick Toy Manufacturer (If You’re a Seller)

There are several factors to consider when choosing a partner for your building brick toy business. Here’s are some things to look out for:

1) Product Quality and Safety

Ensure that the manufacturer follows safety standards like ASTM and EN71. The bricks should be made from durable, safe materials like ABS plastic, and the production process should minimize defects to ensure high quality.

Another thing worth looking out for is whether the seller has ISO certification or not.

2) Pricing

Compare prices from different manufacturers to find one that offers the best value. Some countries, like China, tend to offer lower prices due to cheaper labor, while manufacturers in places like Mexico or Europe may offer faster shipping or fewer supply chain problems.

3) Customization Options

If your business needs custom designs or special packaging, make sure the manufacturer can handle that. Being able to add your brand’s unique touch to the bricks or packaging can help set your products apart.

4) Production Capacity and Lead Times

Check if the manufacturer can meet your order size, especially during busy seasons. You also want to make sure they can deliver on time, without long delays.

5) Shipping and Logistics

Think about where your main market is and how far your products will need to travel. A manufacturer in Mexico will have lower lead times when shipping to North America than one in China, saving you time and money.

6) Reputation and Reliability

Look for manufacturers with good reviews and a proven track record. Reliable customer service and on-time delivery are important for building a successful long-term partnership.

7) Sustainability

More and more consumers care about the environment. Consider working with a manufacturer that uses eco-friendly methods, like using recyclable materials or reducing energy consumption during production.

Frequently Asked Questions

Is LEGO made in the USA?

No, LEGO doesn’t currently manufacture products in the United States. For the North American market, LEGO uses its large factory in Monterrey, Mexico, which handles molding, decoration, and packing. However, LEGO has announced plans to build a carbon-neutral factory in Virginia, expected to be operational by 2025–2027.

Does LEGO manufacture everything in-house?

Yes, LEGO maintains tight control over its production process by manufacturing nearly everything in-house. From brick molding and printing to packaging, LEGO owns and operates all major factories in Denmark, Mexico, Hungary, Czech Republic, China, and soon, Vietnam and the U.S. This ensures consistent quality across global markets.

Are all LEGO bricks made from ABS plastic?

Most LEGO bricks are made from acrylonitrile butadiene styrene (ABS), a durable, high-quality plastic known for its color retention and strength. However, LEGO has introduced sustainable materials in some parts, like sugarcane-based polyethylene for certain plants and accessory elements, as part of its push toward eco-friendly bricks.

Can I buy directly from LEGO as a business?

No, LEGO does not offer direct wholesale or OEM supply for resale. If you’re a seller or distributor, you’ll need to go through authorized distributors or work with contract manufacturers that specialize in LEGO-style building bricks. Just make sure to avoid copyright or patent infringement if you’re creating compatible products.

Is Every Brick Building Toy Called Lego?

No, not every building brick toy is called “LEGO.” LEGO is a brand name for the toys made by The LEGO Group.

Other companies, like Mega Bloks and Kre-O, make similar brick toys, but these are not LEGO. These brands use their own names and designs, even though their bricks can often fit with LEGO bricks.

So, “LEGO” refers specifically to the products made by The LEGO Group, and other building brick toys are different brands.

Which Countries Have LEGO Production Facilities?

LEGO sets are manufactured in multiple countries, including China, Denmark, and Mexico. The company has expanded its factory in Jiaxing, China to meet the growing demand in Asia.

They also have production facilities in Monterrey, Mexico, catering to the American and Mexican markets.

To become a LEGO authorized seller, you must first contact LEGO directly by visiting their official website and submitting an application.

The company will review your application, and if approved, they will provide you with the necessary guidelines and requirements to maintain an authorized seller status.

Be prepared to meet LEGO’s strict quality and branding standards.

How to Identify Fake or Knock Off LEGO Sets?

To distinguish between genuine LEGO sets and knockoffs, pay close attention to the following details:

- Quality of the plastic. Genuine LEGO bricks are made from high-quality ABS plastic, while knockoffs often use cheaper materials.

- Logo. Check for the official LEGO logo on bricks, packaging, and instructions. A fake or counterfeit product may feature a different logo or no logo at all.

- Missing or incorrect parts. Knockoff sets may not include all the pieces needed to complete a build or have pieces that are incorrect in shape or color.

What Are Some Popular LEGO Alternatives?

While LEGO stands out as a leader in the construction toy market, there are several other brands that parents and kids might also enjoy.

Some popular alternatives include Mega Bloks, Playmobil, K’nex, and Nanoblocks. Each of these brands offers a different style or niche, ensuring that there is something for everyone.

What Other Toy Manufacturers Can You Find in China?

China is home to a vast number of toy manufacturers, producing a wide variety of products.

For those looking to source wholesale toys from China, consider exploring these toy suppliers who offer a diverse range of toy options for resale.

Always be diligent in vetting suppliers to ensure product quality and ethical manufacturing practices.

Where Does Lego Get Raw Materials From?

Lego primarily sources its raw materials from ABS (acrylonitrile butadiene styrene) plastic, which forms the core of its famous bricks.

These ABS granules are delivered to Lego factories in bulk, where they are melted and molded into the iconic pieces.

The company also uses a different polymer, styrene-butadiene-styrene (SBS), to make the tires for Lego vehicles

Choosing the Right Partner

LEGO’s production strategy shows how important it is to choose the right locations.

While China plays a key role for the Asian market, LEGO also has factories in places like Denmark, Mexico, and the U.S. These diverse locations help LEGO take advantage of cost savings, skilled workers, and quick access to markets.

If you’re looking for toy manufacturers, understanding these strategies is key.

Working with a sourcing agent like NicheSources can help you find the best manufacturers and ensure your products meet your needs for quality and cost.

To learn more, request a free quote from NicheSources and see how outsourcing your production can help your business succeed.