When you order products from a manufacturer, it is important to concisely state all your requirements upfront. If you don’t, it leaves room for misinterpretation which could lead to them delivering goods that do not meet your standards.

On the flip side, it would be cumbersome for suppliers if every buyer shared their requirements in different formats. Product specification sheets were, therefore, designed to create a more standardized way for buyers to outline product details for suppliers.

If you have never encountered a product specification sheet before or are having a hard time creating one, this is the right blog for you. Settle in and read on as we cover all the basics about how they work, how to create one, and share samples from different industries.

Let’s get into it, shall we?

What Are Product Specification Sheets?

A production specification sheet is a document that outlines your requirements of how a manufacturer should manufacture your products.

On the other hand, if you are sourcing ready-made products, a product specification sheet guides the supplier or sourcing company on exactly what kind of products you want.

Why Do You Need a Product Specification Sheet?

A product specification sheet plays several key roles in the manufacturing process. They include:

Providing Instructions

A product specification sheet comprises guidelines on how to make your products.

The production team thus uses it as a point of reference any time they need to make production decisions such as what materials to use or what colors to incorporate.

Providing Product Insight

Manufacturing is more than just putting materials together to make a product. Your manufacturer also needs to understand what the goal of the product is to ensure that it is optimized for its purpose.

Outlining the functions of your product in a product specification sheet, therefore, gives your manufacturer context and helps them serve you better.

Quality Inspection

A good product specification sheet should indicate the quality standards that you expect for your products. You can also include any legal or health requirements that are stipulated for that type of product in your country.

This too will serve as a point of reference for your manufacturer. They will know what product quality is or is not acceptable to you.

After production, you can use the specifications you provided as a checklist during quality inspection. If the goods meet the indicated standards, then you can approve delivery. If not, you can reject them and ask for replacements or alterations where possible.

Improving Efficiency

Clear instructions help the manufacturing team work within the budget and the anticipated timelines of production. If the instructions are followed with precision, the team can also avoid errors which can result in returns and other losses.

Obtaining Precise Quotes

The cost of manufacturing a product is based on unique factors such as size, materials, finishes, and even the production processes applied.

Consequently, providing detailed requirements of the products you want enables manufacturers and suppliers to provide precise price quotations.

What to Include in a Product Specification Sheet

There is no defined way to write a product specification sheet. This is because:

- Different industries have different requirements regarding specific details.

- Some companies recommend particular formats that their clients should use.

- The format and contents of a product specification sheet may vary depending on whether you are addressing it to a product manufacturer or a sourcing agent.

That said, here are some basic details that apply to most products and may thus be worth considering for your product specification sheet.

The Product Overview

Think of this as offering your manufacturer/supplier an introduction to the product you require. The introduction can include:

- The name of the product.

- Reference photos.

- A brief overview of the product e.g. how it works, its components/parts, what systems or technologies it runs on, etc.

- The anticipated functions of the product.

- Your target market and the benefits you want them to obtain from the product.

Product Details

Product details outline fundamental design or formulation details such as:

- The exact materials to be used

- Dimensions

- Product weight

- Colors (quoted from a specific pallet)

- Texture and finishes

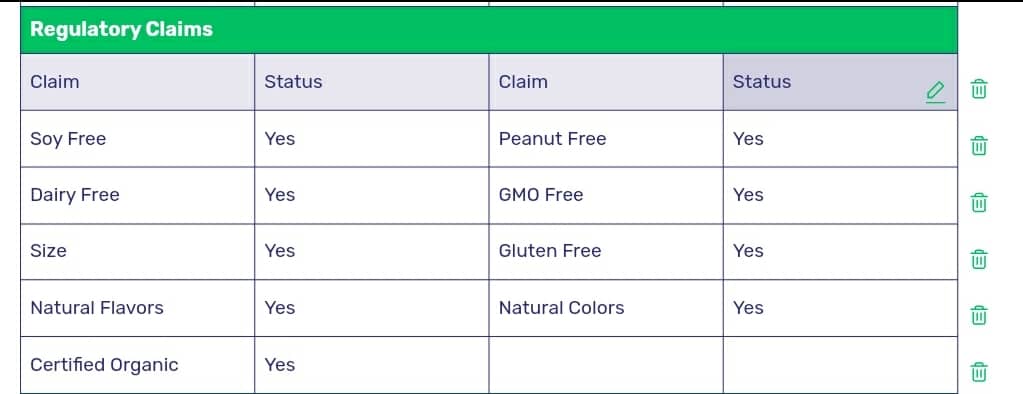

Quality Standards and Certifications

Carefully research and outline:

- The acceptable quality standards and what can be considered a defect during quality inspection.

- The recommended safety standards for that product in the country of import.

- Any certifications that you may require from the supplier so that authorities in your country can ascertain that your goods are compliant.

Packaging and Branding

This section comprises guidelines on how you would like your products to be packaged and branded after production. It may include details such as:

- The preferred packaging medium e.g. boxes, plastic or glass jars, bottles, etc.

- How the packaging should be sealed.

- Product labeling i.e. what style of labeling should be used and what details should be included on the labels.

- Branding i.e. specify the appropriate use of logos and any other trademarks on the packaging.

- The number of items that should be included in a unit of packaging.

- Guidelines for inspecting the packaging.

Examples of Product Specification Sheets

Now that we have demystified product specification sheets, let’s take a look at some examples that you can use as inspiration to create your own.

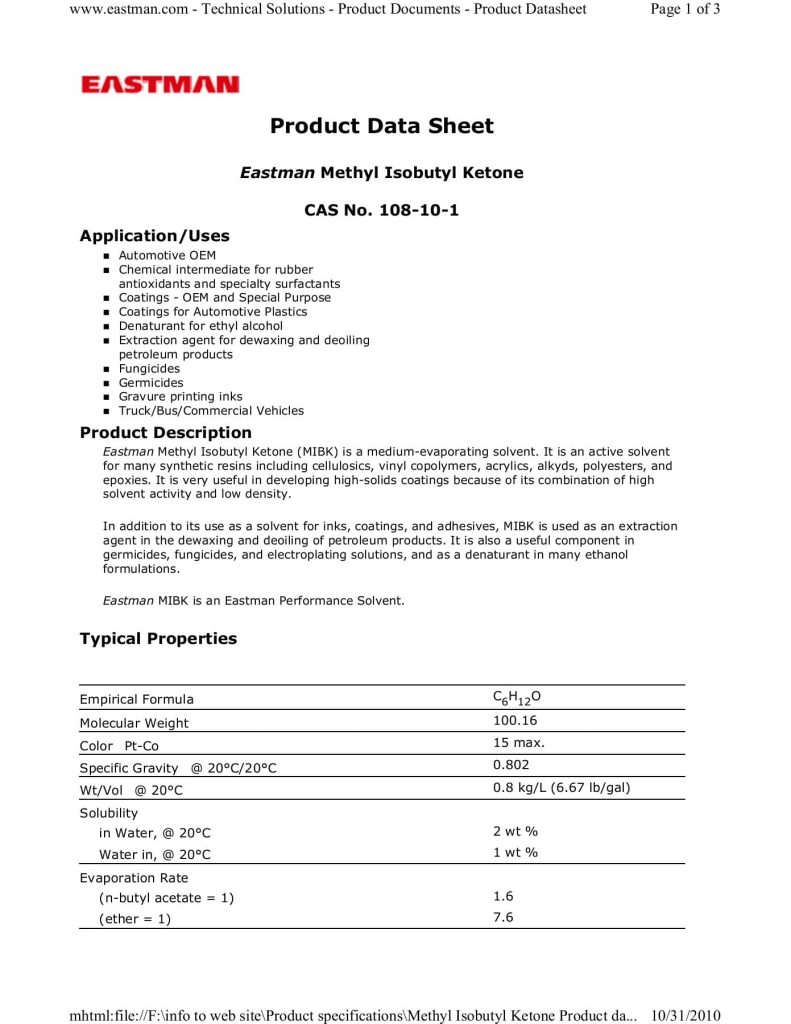

Example 1

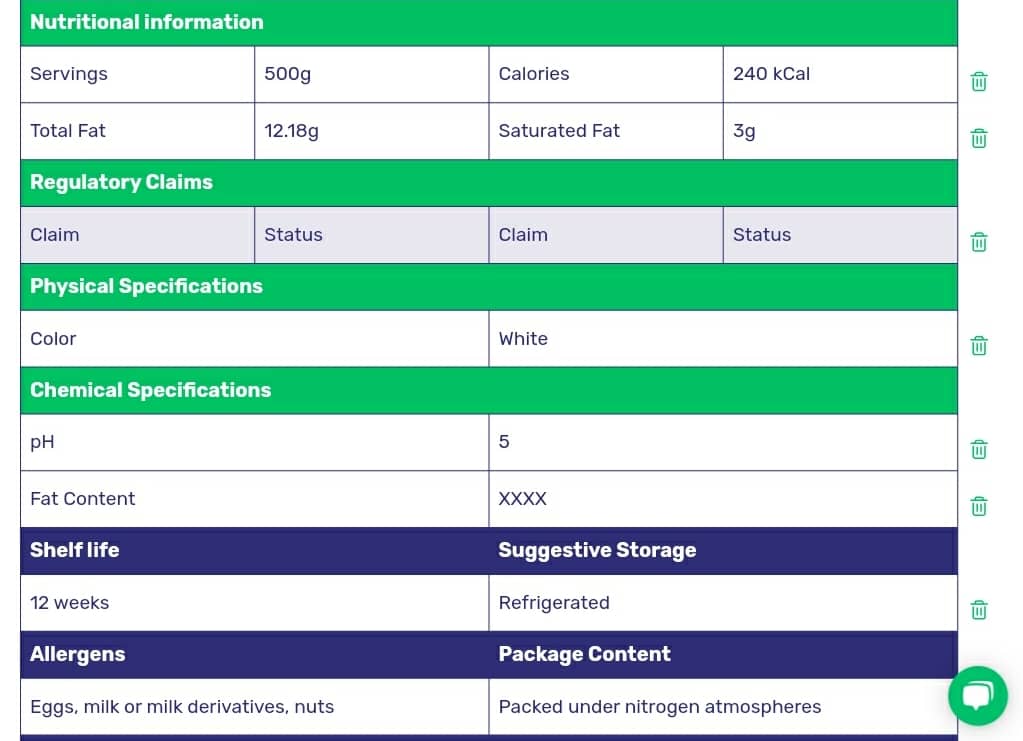

In this case, the product specification sheet begins with a general introduction to the product and then proceeds to technical details. The first part thus creates the context for the reader to understand the second part.

The second part outlines the empirical data about the product’s formulation which can be used as guidelines during production.

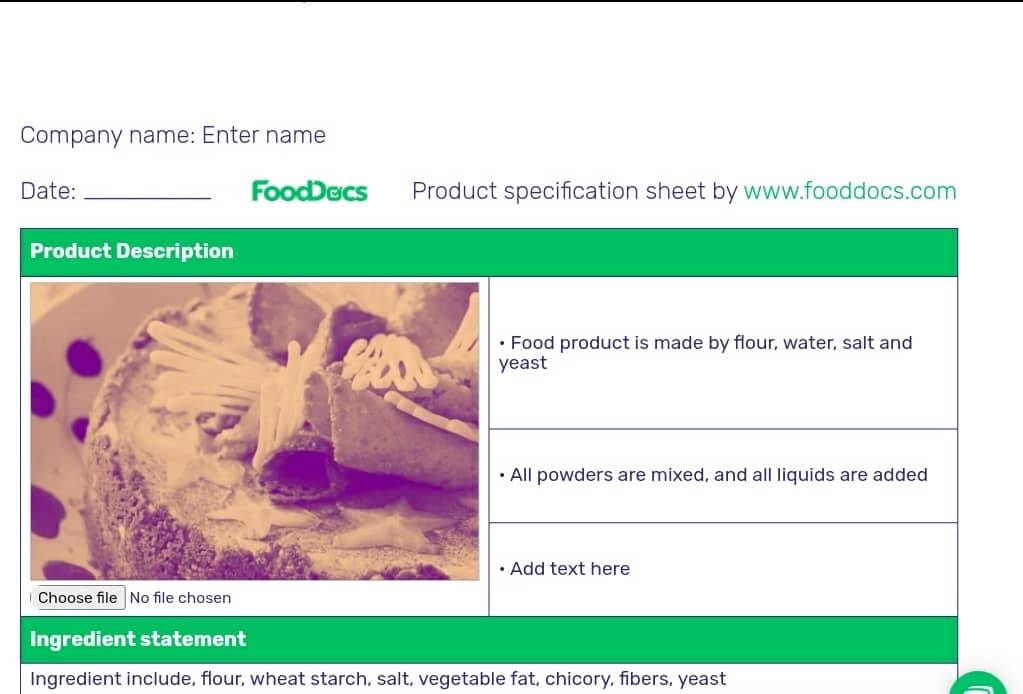

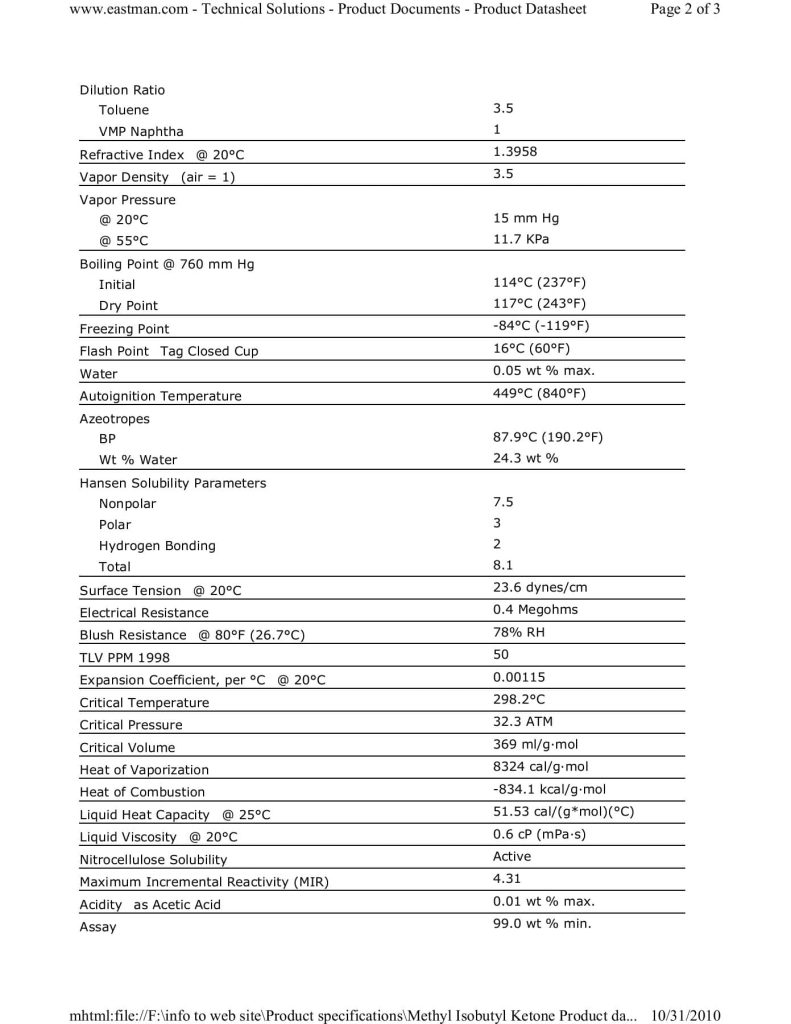

Example 2

In this example, let’s shift focus to some essential details that were not present in the first product spec sheet. They include:

- An illustration of the product in question.

- Product features and benefits to provide context to the manufacturer about what the finished product should offer to consumers.

- Packaging details

- Labeling details including barcodes

- Shipping information

It is also worth noting that while this spec sheet is quite detailed, it is still brief and concise.

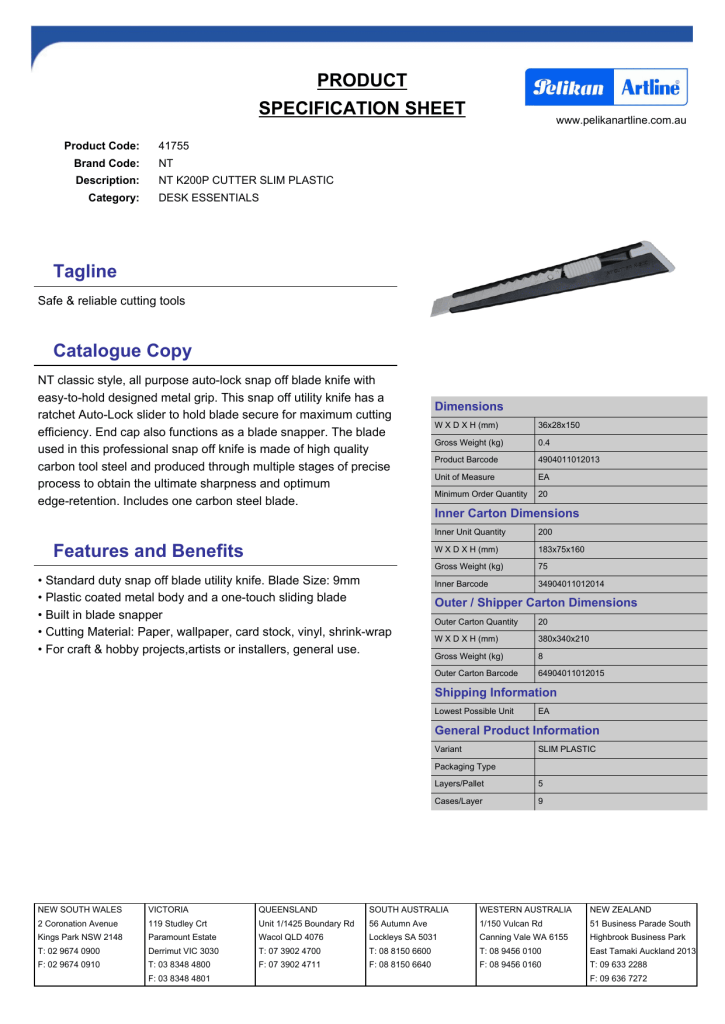

Example 3

If you are creating a product specification sheet for a product that requires careful management, consider including a section that highlights such concerns.

The manufacturer may not know as much as you do about your formulation and sharing such information could help handle the situation with appropriate caution. Below is an example of how to draft such a section.

How to Create a Product Specification Sheet

Creating a product specification sheet sounds like a highly technical and challenging task but it is not. As long as you understand the product and how it works, the rest of the process is a walk in the park.

Here is a step-by-step guide to help you get it right on the first try.

Complete Your Product Development Process

Product development is the process of creating a new product or modifying one that is already in existence. The goal is usually to provide a new solution to customers or gain an edge over your competitors in the market.

It is important to take your time with this process because:

- Good product development helps you come up with good products.

- The product development process gives you a chance to learn about the product in depth. This includes details such as the materials used, why those particular materials were chosen, the product functionality, its benefits, and much more.

- Testing and prototyping the product during its development allows you and your team to identify flaws in the design and make any necessary corrections.

If you are sourcing ready-made goods, this step may not be relevant. However, it is still important that you obtain different samples of the product you are sourcing and evaluate them. This will help you make a more informed product specification sheet.

Outline All the Product Specifications

Write down all the pertinent details that a manufacturer would need to know about your product to produce it. No detail is too small.

Also, do not assume that a manufacturer knows what you require just because they specialize in making that type of product. Most handle each project uniquely based on the instructions of the client. They can only advise you if necessary.

Of course, writing this in-depth product summary involves lots of details. So, making it a team effort where staff from different departments can consult and agree on details before they go into the summary.

Organize the Summary into Segments

Once all the details are outlined in the summary, start breaking down the summary into segments.

For example, the part of the summary introducing the product can be categorized as the ‘product overview’.

You can then go further down the list and organize the rest of the information into sections like those we have outlined above i.e. product details specifications, quality, certifications, etc.

As you do this, feel free to also make the descriptions shorter and direct. However, do not leave out any crucial information in pursuit of brevity.

Choose a Template

There are many ways to find a suitable template for your product specification sheet. You can:

- Use the examples we have shared above or look up other alternatives on the internet.

- Ask your manufacturer to share a template or a sample of a specification sheet that they have received before.

- Create your own by opening a blank document, inserting a table, and customizing the table to accommodate the specs you want to present.

Tip: Aim for an organized template that presents your specifications clearly and is easy to read.

Arrange the information segments you had created in the previous step in the template that you choose. Edit and highlight important sections like headers or details that require extra attention.

Add Images or Illustrations

Images or illustrations can help provide better guidance and context for the specifications you provide. Therefore, do not hesitate to include them in sections of the sheet where they are relevant.

Review the Product Specification Sheet

Take time to read through the product specification sheet you have created. Look out for errors and any details that you may have omitted. Additionally, ensure that all the included details are comprehensible and leave no room for ambiguity.

Share copies of the sheet with your team for feedback and make any necessary changes before submitting it to your manufacturer, supplier, or sourcing company.

What Format Should the Product Specification Sheet Be in?

Word and Excel are some of the most convenient platforms to use when creating a product specification sheet. However, once you are done, it is best to send the document to your supplier in PDF format.

As we have highlighted above, product specification sheets are a reference point for both you and your supplier. Sending them in PDF format prevents the recipient from editing them. They, therefore, can not dispute your instructions later on.

Product Specification Sheet Templates

Product specification sheet templates provide a bare structure that you can fill with the details you would like to share. They come in different designs and all you have to do is pick one that suits your spec details.

Below are some template examples to consider.

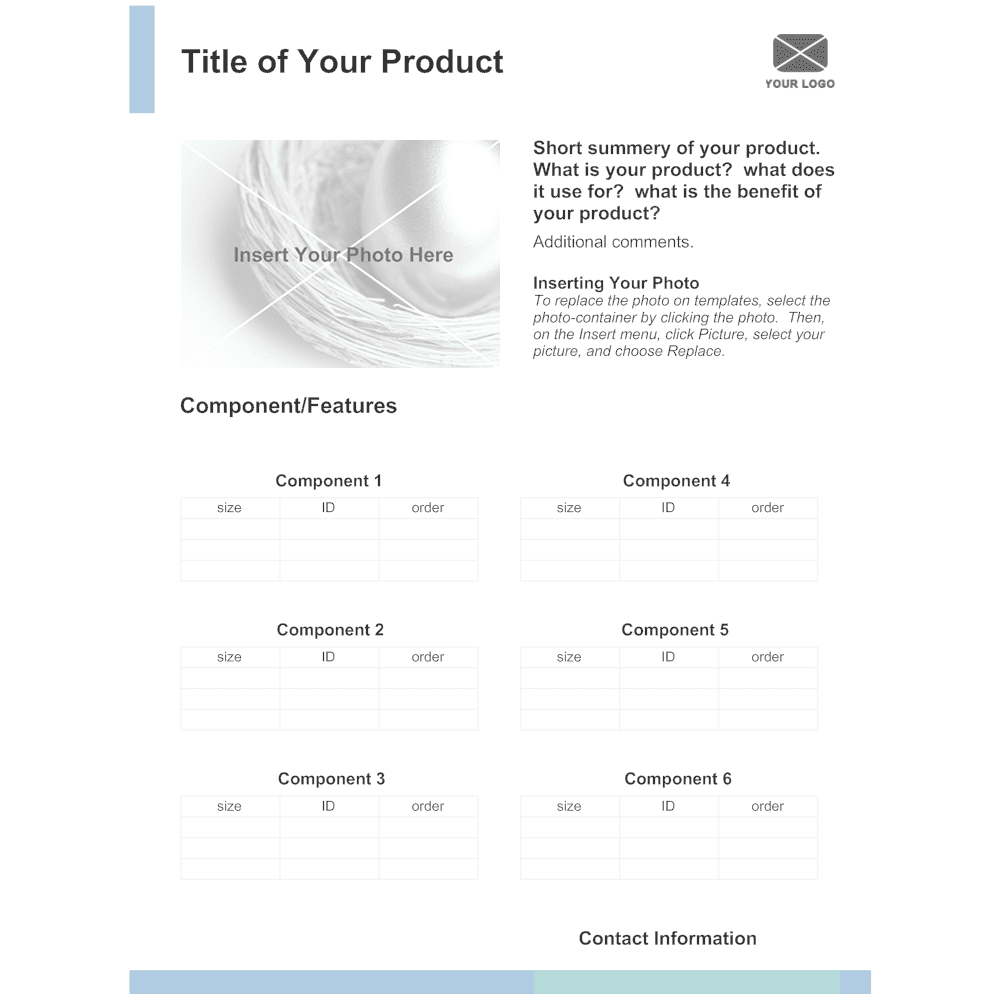

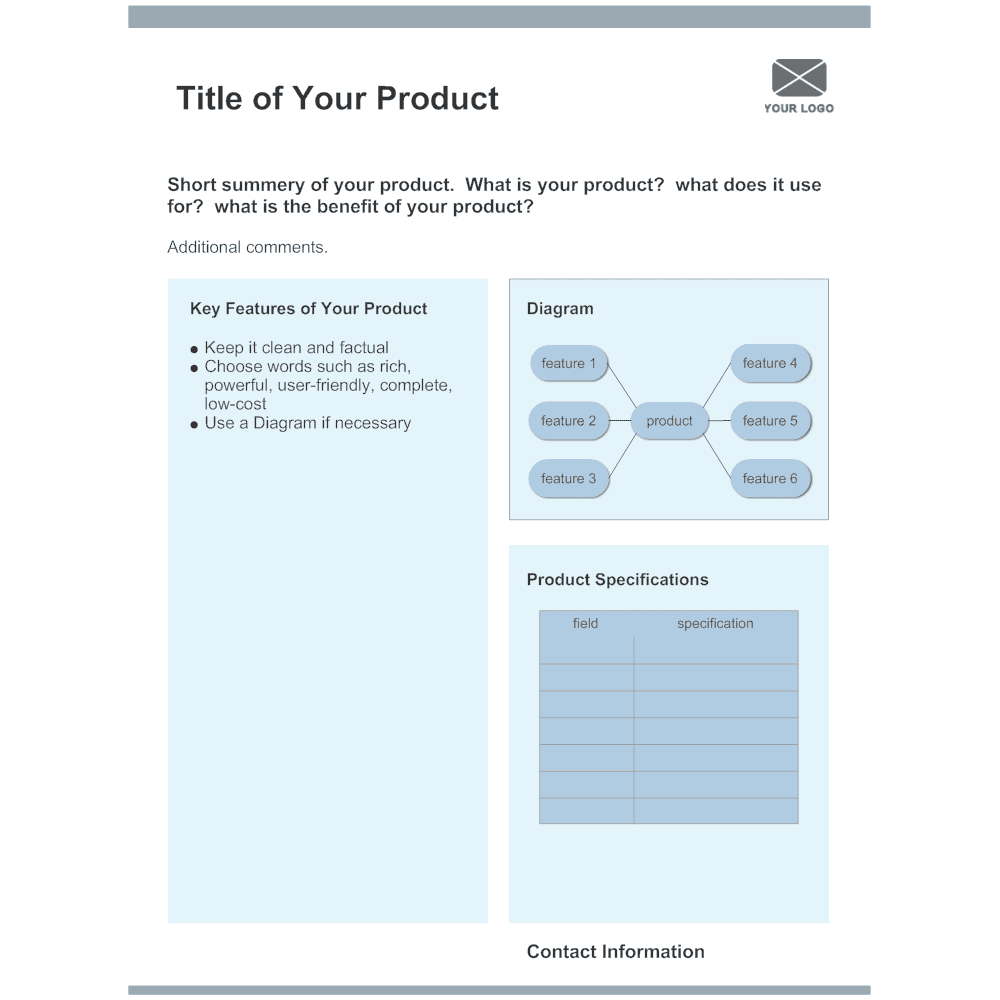

Template 1

This template would be easy to adapt to a wide variety of products. You can fill up the component sections any way you like and present whatever specs apply to your product. To sum it up, it has room to cover all the basics.

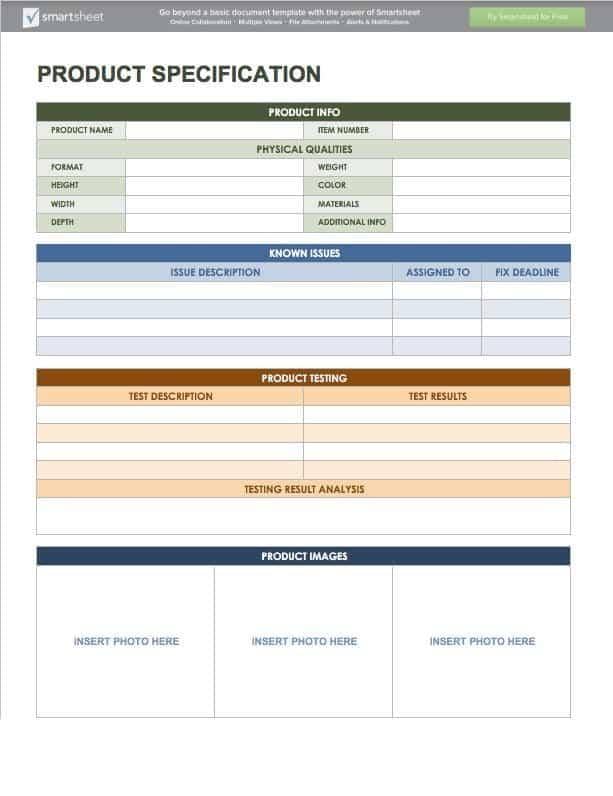

Template 2

You may not always find the answers you need during the product development stage. As a result, you may have to collaborate with the manufacturer to find solutions before venturing into mainstream production.

This type of template would be ideal for such situations or instances where you are providing product specs for a prototype or sample.

Template 3

It may be easier to highlight some products using graphics more than words. This type of template allows you to do that but also summarize the product features to support the graphics you present.

FAQs about Product Specification Sheets

What Is the Difference Between Specifications and Features?

Product specifications and product features are related in that they refer to the qualities of an item. However, features provide general descriptions while specifications offer very particular details.

Take a wine glass, for example. While describing its features, you can say that it has a short or long stem and a wide or narrow goblet. In contrast, its product specifications would state the exact length of the stem as well as the diameter and height of the goblet.

How Do You Create Product Specifications?

Product specifications can be created through product development or research.

Product development is ideal for situations where you are creating a new product or customizing one that already exists. As you work through it, you will establish the right specifications for the type of product and functionalities that you are trying to achieve.

Research, on the other hand, works best when you are sourcing ready-made products. It allows you to discover:

- The different designs (of the product you are sourcing) available in the market.

- The material options.

- Quality standards for the product.

- Size options.

- Color combinations.

- Packaging and branding styles.

Once you identify the features that you prefer, you can share them with your supplier through a product specification sheet.

What Is a Manufacturer Specification Sheet?

A manufacturer specification sheet is an outline created by the manufacturer. It comprises all the steps, materials, machinery, graphics, and production techniques that will be used to manufacture a product.

The document aims to provide guidelines to the production team but it is drafted by the manufacturer and not the client. It should thus not be confused with a product specification sheet prepared by a client to instruct a manufacturer.

For better context, here is how these different documents work.

- A client drafts a product specification sheet for the product they want.

- The client presents the product specification sheet to the manufacturer.

- The manufacturing team analyzes the product specification sheet and understands what the client requires.

- The manufacturing team creates a manufacturer’s specification sheet to guide staff in the factory on how that product will be made.

To Sum It Up

Product specification sheets strike many entrepreneurs as very technical documents that can only be drafted by a handful of experts.

Yet, on the contrary, you too can draft yours as long as you understand the products you want and consult with relevant professionals.

There is equally nothing wrong with delegating the process altogether. We, in particular, are well-experienced in product development and product sourcing. Subsequently, we can draft proper product specification sheets to facilitate both services.

Simply send us a detailed brief of the products you require and request a free quote at any time.