A consistent supply of goods enables you to keep up with your customers’ demands. It, in turn, boosts your customer retention, builds up your reputation as a reliable seller, and helps keep your cash flows active.

Nevertheless, despite your best efforts, supply chain challenges are sometimes inevitable. They can cause stockouts and leave you and customers in quite a dilemma.

On the upside, safety stock can be a game changer if you have been suffering such mishaps in your business. Not familiar with the concept? Well, then do come along as we explore what it means, how it works, and how you can implement it in your business.

What Is Safety Stock?

Safety stock is extra inventory that a business holds to cushion itself from supply chain disruptions.

For example, if you sell 300 toy sets in a month, then you would probably order about 1200 toy sets per quarter. However, if you would like to have some safety stock, then you could choose to adjust your order to 1500 toy sets per quarter.

Note that you would have an extra 300 toy sets more than your forecasted sales. Therefore, if you sell out the expected 1200 toy sets and there is a delay in getting more inventory, you can sell the extra 300 sets in the meantime.

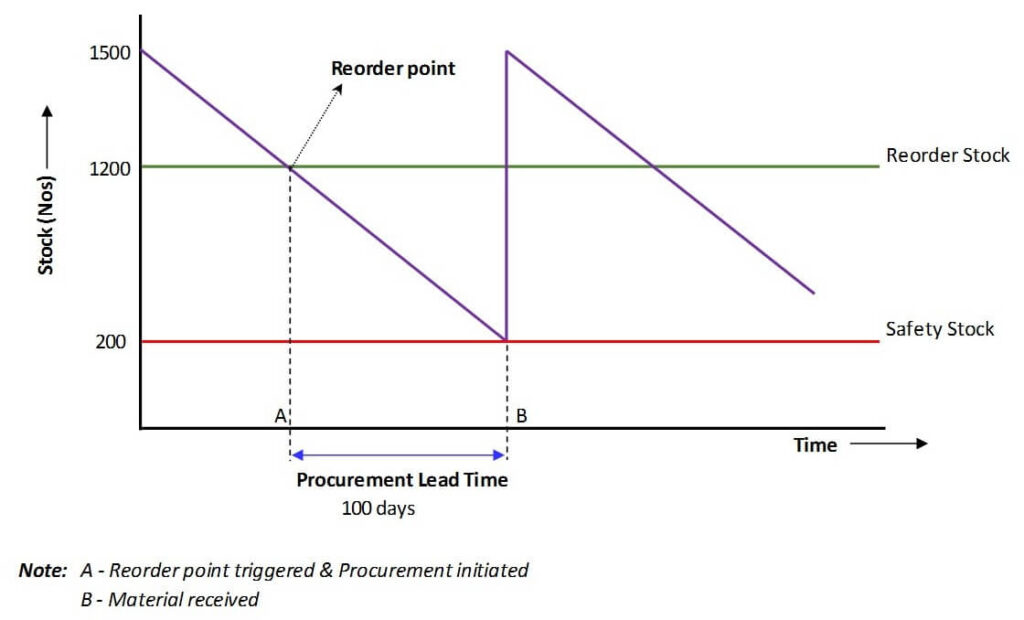

In a nutshell, safety stock is purely a contingency measure. It should not affect the reorder point of a business in any way and should only be tapped into when there is an inevitable need.

Why Is Safety Stock Important?

Safety stock protects your business from:

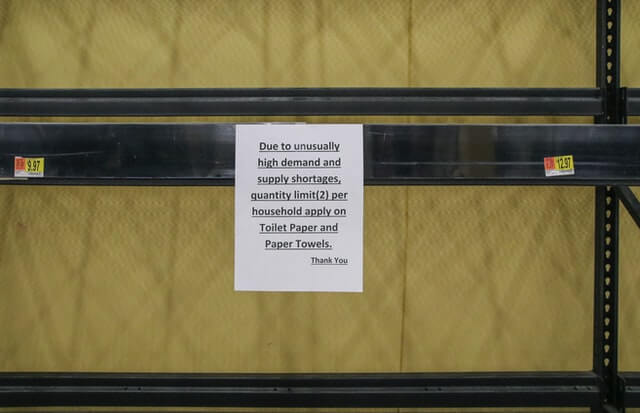

Shortages

Product shortages are often caused by events such as scarcity of raw materials, labor strikes, financial crises, and even trade restrictions. Most parts of the world, for example, are currently facing wheat shortages because of the conflict in Europe.

Safety stock allows you to stay in business during such instances. It tides you over until you can replenish your stock or until normal supply is restored.

Surges in Demand

Most businesses manage inventory based on forecasts of sales or the market forces of demand and supply. However, demand can sometimes rise unexpectedly due to:

- Sudden necessity – for example, when the pandemic began, demand for face masks, sanitizer, tissue, and food supplies shot up overnight.

- An expected rise in price – most customers tend to stock up on products if they anticipate a price hike. More so if it is a product that they use regularly or the price hike is significant.

- Seasonal demand – products often sell out fast when they are in season. This can cause longer lead times among suppliers and even shortages.

Safety stock, in this case, allows you to enjoy the high sales that come with increased demand without worrying about running out of stock.

Logistical Challenges

Sourcing and shipping goods can be an unpredictable affair. Port delays, bad weather, high cargo traffic, and human error can all cause unforeseen delivery delays.

Keeping safety stock shields you from the inconveniences that arise from such delays.

Customer Loss

When you run out of stock, it means that customers can not get the products that they need from your store. If their need is urgent or your lead times are too long, you may lose them to your competitors.

The only way to escape this noose is to always have a little extra stock to ensure that you can perpetually meet your customers’ needs.

Market Fluctuations

Fluctuations in product prices, demand, and other market forces can hurt your bottom line and the general outlook of your business. Safety stock is thus an important buffer because:

- It gives you some time to adjust to changing circumstances like an increase in shipping costs or a change in suppliers.

- It allows you to gradually introduce your customers to changes in factors like price or even product packaging. This gives you a higher chance of retaining customers compared to overnight changes.

Inadequate Inventory Caused by Forecast Errors

Forecasts are estimates based on previous sales or market data. They are often helpful in determining the optimal inventory levels of a business but there is always a margin of error that you may overlook.

Safety stock allows you to compensate for any shortfalls arising from that margin of error.

How to Calculate Safety Stock

Calculating safety stock is all about finding the right amount of extra inventory that your business should hold. Of course, different businesses have different needs and thus there are multiple formulas for calculating safety stock. They work as follows:

The Universal Safety Stock Formula

This is the general safety stock formula used by businesses across industries.

Safety Stock = (Maximum Daily Sales × Maximum Lead Time) – (Average Daily Sales × Average Lead Time)

This formula is suitable for most businesses with a normal demand schedule.

Example:

Let us consider that company X reports the following figures:

- Total Annual Sales = 300,000 units

- Max. Sales Per Day = 1,500 units

- Max. Lead Time = 30 days

- Average Sales Per Day = 820 units

- Average Lead Time = 14 days

Company X’s safety stock would work out as follows:

(1,500 × 30) – (820 ×14)

Safety Stock = 33,520 units/year

Fixed Safety Stock

Fixed safety stock is a situation where a business determines safety stock based on the average number of units (of a product) it sells daily. The common formula used in this approach is as follows:

Fixed Safety Stock = No. of Days × Average Daily Sales or Maximum Daily Sales

The number of days you choose to use in this formula should, ideally, be based on your average lead times. Therefore, this method is recommended for businesses with fairly consistent demand trends and minimal supply chain disruptions.

Example:

Let us assume that Company X’s supplier has an average lead time of 30 days. Additionally, it fully shuts down for 14 days every year for the Chinese New Year.

This means that Company X can only receive additional inventory 30 days (give or take) after the supplier resumes operations. Therefore, if Company X sells 200 units every day, it can set its fixed safety stock for Q1 as:

30 days × 200 units

Fixed Safety Stock = 6,000 units

Heizer and Render’s Formula

Heizer and Render’s formula is more nuanced in that it considers variations in the factors that impact the inventory of a business. It is calculated as below:

Safety Stock = Z Score × Standard Deviation in Lead Time (σLT)

A Z Score represents your desired service level. A service level is the percentage of your forecasted orders that you plan to fulfill without experiencing any stockouts.

For example, if you have a service level of 90%, it means that there is only a 10% chance that you will run out of stock before your supplier delivers more. Your Z score is a co-efficient of the 90% service level.

On the other hand, the standard deviation lead time is the rate at which your supplier’s lead times vary. For example, if their typical lead time is 2 weeks, your standard deviation lead time is a ratio of how often and by how many days they deviate from it.

This method of calculating safety stock is ideal for a business that faces fluctuating lead times but has relatively steady demand.

Example:

If your service level is 90%, your corresponding Z-score is 1.65.

Meanwhile, if the average lead time is 14 days, the standard deviation in lead time works out as follows:

| Expected Lead Time | Actual Lead Time | Deviation |

| 14 Days | 14 days | 0 |

| 14 Days | 20 days | +6 |

| 14 Days | 10 days | -4 |

| 14 Days | 14 days | 0 |

| 14 Days | 12 days | -2 |

Standard Deviation in Lead Time = Average Expected Lead Time + Average Variance

14 + [ (0+6-4+0-2)÷5 = 14

Therefore, the safety stock level would be:

1.65 × 14

Safety Stock = 23.1 units

Greasley’s Method

Greasley’s Method provides a more wholesome approach to calculating safety stock. It considers fluctuations in both lead time and demand.

Safety Stock = Z Score × Standard Deviation in Lead Time × Average Demand

This may be a more suitable approach for businesses experiencing seasonal demand or fluctuations due to market trends.

Example:

The Greasley method requires a Z score, the standard deviation in lead time, and average demand.

In the previous example, we had established a Z score of 1.65 and a standard lead time deviation of 14 days.

Average Demand = Total Units Sold ÷ Time

So, if Company Y sold 30,000 units in 5 months (150 days), its average demand is 200 units per day. Its safety stock for 5 months, based on the Greasley method, would thus be:

1.65 × 14 × 200

Safety Stock = 4,620 units

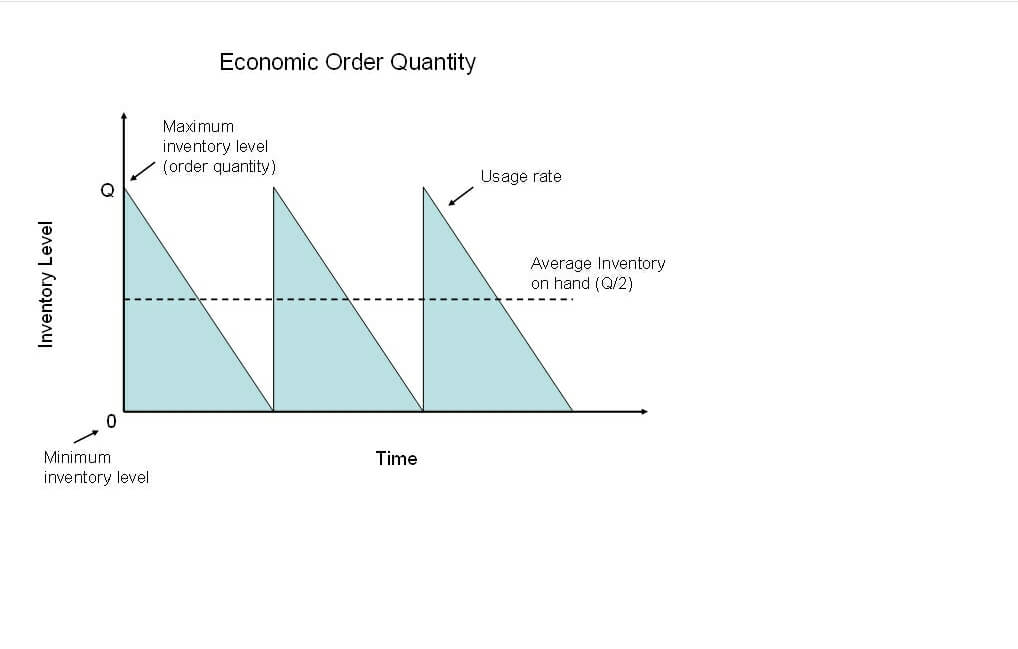

The EOQ Formula

The Economic Order Quantity (EOQ) of a business is the optimal inventory level it should order to ensure it only incurs an optimal inventory cost.

EOQ is calculated as follows:

EOQ = √[(2 ×Demand Rate × Cost Per Order) ÷Holding Costs]

- Demand rate – the number of products a business sells over a set period.

- Cost per order – all the expenses you incur to restock a product i.e. packaging, handling, shipping, last-mile delivery, and intake.

- Holding costs – the expenses you incur while storing the inventory.

The idea here is to first work out the EOQ of your business and then use it as a baseline to estimate how much safety stock you need.

This formula assumes that all the variables are constant and is thus only suitable if your business enjoys relative stability in demand, supply, and costs.

Example:

If Company Y sells 200 units per day its demand rate is 73,000 units per year.

Let us further assume that it costs $3/unit to place an order and $5 to store the inventory.

The EOQ would be:

√[ (2 × 73,000 × 3) ÷ 5]

EOQ = 296 units

Time-Based Calculation

A time-based calculation determines safety stock based on:

- Sales history – this includes your sell-through rates for each product, inventory turnover, and stockouts you may have experienced.

- Demand forecasts – these are your data-based projections for the number of product units you are likely to sell in the future.

This method is recommendable if you have enough data to use for your forecasts. As such, it may not be ideal for startups or a business that does not maintain meticulous records.

What Factors Influence Safety Stock?

As we have learned above, you can set your safety levels in different ways depending on the nature of your business. Here are some factors worth considering as you make that decision.

Supplier History

Evaluate your supplier’s performance history by considering:

- How often do they deliver on time?

- What is their average lead time?

- Are there seasons or events that impact lead time?

- How many orders have they fulfilled in full?

- What is the average number of rejects per order?

If they are highly reliable then you can get by on low levels of safety stock. However, if their performance is inconsistent, it would be wise to have significant safety stock levels to compensate for their shortcomings.

Product Popularity

Popular products are money-makers for any business and have a higher probability of selling out. In comparison, less popular products have a lower sell-through rate and hardly go out of stock before you can replenish their inventory.

Subsequently, it is advisable to have higher levels of safety stock for your best-sellers and lower levels for slow-moving goods.

Lead Times

Restocking involves manufacturing, shipping, and onboarding lead times. As such, consider the total duration of all these lead times when deciding how much safety stock you require.

The rule of thumb is to maintain more safety stock if lead times are long or unpredictable and low safety stock if lead times are short.

Seasonality

Seasonal demand causes your sell-through rates to vary from time to time. Consequently, if you sell seasonal products, it may be ideal to maintain high quantities of safety stock during high seasons and low quantities during low seasons.

The Cost of Stockouts

How much would it cost your business if you run out of stock? Try to quantify this both in terms of actual sales and opportunity costs like the loss of customers.

Take a step further and weigh the cost of a stockout versus the cost of managing safety stock. Which is higher?

If the cost of a stockout is higher than inventory costs, then you are better off investing in high quantities of safety stock.

However, if there is little or no cost incurred due to a stockout, then it is advisable to maintain low safety stock. It will keep your inventory costs manageable and save you from tying up your capital.

Storage Space

The amount of storage space you have may limit how much safety stock you can hold. For example, you may need 500 product units of safety stock but you may only have room to store 200 units.

In such instances, you may have to work with the space you have. However, if there is a pressing need to have more safety stock, you may have to hire extra storage space or find ways to improve your supply chain so that your business can get by on less safety stock.

How Much Safety Stock Should a Business Hold?

In general, a business should hold enough safety stock to ensure that it can comfortably operate when its inventory replenishments are delayed.

However, the optimal levels of safety stock can vary between businesses based on some of the factors we have outlined above.

Subsequently, it is best to review optimal safety stock on a case-by-case basis as opposed to taking a one-size-fits-all approach.

How Should a Business Optimize Safety Stock?

Safety stock ties up capital, takes up storage space, and comes with maintenance costs. If it is not optimized, it may become more of a liability than an asset.

So, let us discuss some ways to optimize your safety stock, shall we?

Evaluate Your Reorder Point

An optimal reorder point ensures that you order replenishments from your supplier while still having enough stocks to sustain you until they can deliver more. It should, therefore, factor in:

- Your supplier’s lead times

- The amount of working inventory you will require during that lead time

If your reorder point is not optimal, you will probably fall back on safety stocks very often. This can cause you to hold more safety stock than necessary.

Nevertheless, if you adjust your reorder point to a more appropriate time, then you will likely have a better inventory flow. You will, in turn, also be able to work out an optimal quantity of safety stock.

Choose a Suitable Calculation Method

Using an unsuitable method of calculating safety stock could result in you holding excess or inadequate safety stock.

Therefore, before choosing a formula, take time to understand the internal and external factors that impact your sales and inventory flow. Your findings will make it easier to identify a suitable way to calculate your optimal safety stock.

Improve Your Supply Chain

Safety stock should only be a buffer against inevitable supply chain disruptions. Therefore, you can optimize it by correcting avoidable shortfalls in your supply chain.

For example, if your supplier has untenably long lead times, consider finding a different supplier that has shorter lead times. You could also look into solutions such as:

- Faster shipping – if your current shipping method takes too long, consider using an alternative carrier or a different shipping mode like express shipping.

- Working with a sourcing agent – a sourcing agent can help you expedite shipping if your supplier’s shipping approach takes too long. They could also coordinate just-in-time delivery to help you improve your inventory flow.

- Backup suppliers – having a backup supplier can help sustain your supply chain if your primary supplier is facing shortages, trade restrictions, or other difficulties that hinder their delivery. It may be more efficient than holding bulk safety stock.

Automate Your Inventory Management

Automated inventory management systems collect and organize inventory-related data based on your sales, inventory turnover, stockouts, and other aspects of inventory flow.

The accuracy of such a system would enable you to:

- Make more informed and accurate forecasts

- Determine an optimal reorder point

Subsequently, you would be better equipped to calculate suitable safety stock levels. You would also have an easier time noticing trends in your inventory flow and adjusting your safety stock levels if necessary.

FAQs about Safety Stock

How Often Should I Change My Safety Stock Levels?

Consider adjusting your safety stock levels based on changes in the variables that affect your inventory flow. Variables include factors like lead time and demand.

That said, variables are hardly ever constant. So, it is advisable to observe trends and set timelines for reviews. This could be every quarter, bi-annually, or annually; the more rapid the changes, the shorter your review internals should be.

Is Buffer Stock and Safety Stock the Same?

Yes.

However, in a few industries, buffer stock is specifically the inventory used to cover shortfalls due to a spike in demand. Safety stock, in contrast, is the inventory used to sustain a business during supplier delays.

Is Safety Stock and Minimum Stock the Same?

No.

Minimum stock is the least amount of working inventory that a business can have at any time. If inventory levels go lower, the business will likely experience a stockout or have to tap into its safety stocks.

In comparison, safety stock is inventory that a business holds for emergencies. It only comes into play if a business exhausts its minimum stock before receiving replenishments.

In Conclusion

Safety stock is undoubtedly a necessity for every business. The key, however, is to ensure that you only hold an optimal amount. Anything beyond that would be counterproductive.

Would you like to improve your supply chain and optimize your safety stock? We, at NicheSources, can help you source products within short lead times, store your goods, and arrange timely shipping across the globe.

Simply send us your sourcing requirements, request a free quote, and we will promptly get back to you with well-curated solutions.