Hallmark is the giant of the greeting card industry. For business owners and sellers, Hallmark isn’t just a competitor; it is a textbook example of how to manage a complex global supply chain. The key question is: where are their cards actually made?

The simple answer: It depends on how complex the card is.

Hallmark uses a Split-Manufacturing Strategy.

- Simple, Flat Cards: 70% are made in the USA (Kansas) for speed.

- Complex, 3D, & Music Cards: 30% are made in China and Vietnam because they require hand-assembly and electronics.

This analysis breaks down their suppliers, their strategy, and what you can learn to build your own stationery brand.

Manufacturing Locations by Card Type

Hallmark decides where to manufacture based on the product’s design. They split production into two clear categories.

1. Made in USA: Simple Paper Cards (70%)

- Locations: Lawrence and Leavenworth, Kansas.

- What They Make: Standard paper cards, envelopes, and ribbons.

- Why: Hallmark owns these factories. Keeping production local allows them to restock shelves quickly. If a birthday card sells out, the Kansas factory can print and ship it in days. This speed is vital for basic items.

2. Made in Asia: 3D & Electronic Cards (30%)

- Locations: China (Dongguan, Shenzhen), Vietnam, Sri Lanka.

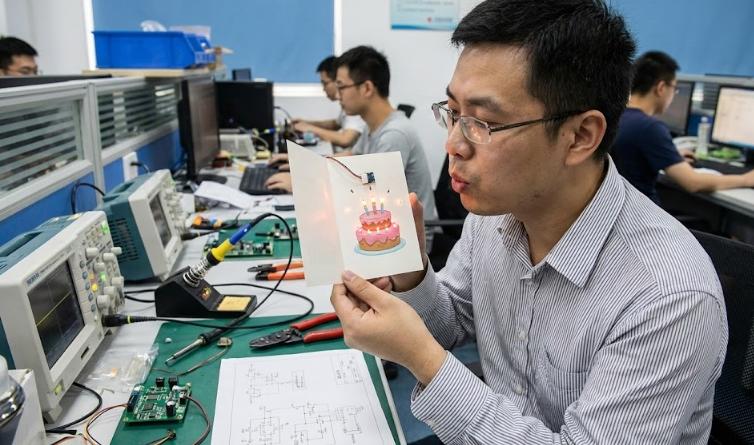

- What They Make: Pop-up cards, musical cards, and resin ornaments.

- Why: A card that plays a song or pops up into a 3D castle requires manual assembly and electronic chips. Automation cannot do this easily. China and Vietnam have the skilled labor and electronic supply chains to do this efficiently.

Key Suppliers in China & Vietnam

Most reports only say “Asia.” As sourcing agents, we look at the specific factories to understand the quality standard.

China: Electronics & Innovation

China is the hub for complex cards. Key suppliers include:

- Hesheng Creative Tech (Dongguan): A core supplier for Hallmark’s electronic cards. They developed patented tech like “blow-out candle” sensors and video cards. They hold certifications from Disney, proving they meet top standards.

- Insight: If you are sourcing complex products, you should look at China Manufacturing Cities like Dongguan, which specializes in combining electronics with printing.

- Haoyang Greeting Cards (Shanghai): They act as a local agent and designer, helping adapt Hallmark’s designs for the Chinese market.

Potential High-End Partners

Industry data points to major printing groups as likely partners for high-end handmade cards:

- Leo Paper Group (Heshan): A global leader in “Pop-Up” books. They have massive teams for hand-gluing complex paper structures.

- Hung Hing Printing: A giant in luxury packaging and rigid boxes, likely producing Hallmark’s puzzle sets and gift boxes.

Vietnam: The New Production Hub

Due to trade shifts, Hallmark is moving some production.

- Dongguan Box (Vietnam Branch): Specializes in Christmas ribbons and gift bags.

- Trend: Data points to Vietnam potentially making up about a third of Hallmark’s total sourcing in 2024-2025. This is a strategy to reduce costs and diversify risk.

3 Sourcing Lessons for Sellers

Hallmark’s model proves that you need the right partner for the right product.

1. Split Your Production If you are sourcing products from China, don’t use the same factory for everything.

- Use automated factories for simple paper goods to keep costs low.

- Use specialized assembly factories (like Hesheng) for premium 3D items.

2. Sustainability is Required Hallmark requires Asian suppliers to use paper with 20% recycled fiber. Suppliers are also developing biodegradable electronic parts. If you want to sell to the West, your supplier must have green certifications.

3. Look for R&D, Not Just Labor Hallmark works with suppliers who invent. Hesheng invented the “video card” technology. To build a lasting brand, you need a manufacturer that offers new ideas, not just printing services.

Read More: Ready to find a partner? Read our guide on How to Find a Manufacturer in China to make sure you find a real factory.

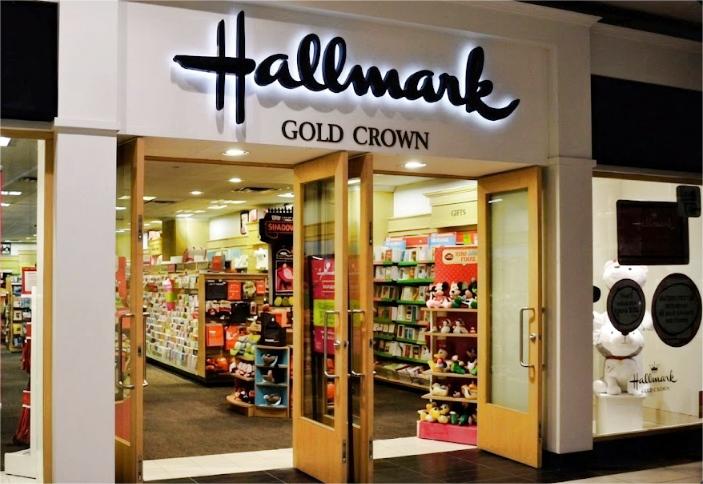

How We Help You Source Stationery

Hallmark has a global team to manage these complex suppliers. You have us.

Sourcing “flat” paper is easy. Sourcing high-quality musical, 3D, or video cards is hard. It requires checking chips, batteries, and paper engineering.

At NicheSources, we specialize in this complexity:

- Verify the Factory: We know which factories in Dongguan can actually handle electronic assembly and which ones are just middlemen.

- Check the Quality: We inspect the hand-gluing and sound chips before they ship, ensuring your brand reputation stays safe.

- Manage the Cost: We can help you split production between China and Vietnam to get the best price.

Don’t just print a card. Engineer a product.

Ready to start? Contact NicheSources today.