ECCO isn’t just another shoe company. Unlike most of its competitors, ECCO makes almost all of its shoes in factories it actually owns.

From tanning the leather to producing the soles, the brand controls nearly every step of the process. That’s rare in the footwear world, where outsourcing is the norm.

So where exactly are ECCO shoes made? The answer takes us from Denmark to Portugal, Slovakia, Indonesia, Thailand, China, and Vietnam.

But the story is bigger than just geography, it’s about how ECCO built a global footprint without giving up control.

In this article, we’ll uncover the manufacturing locations of ECCO shoes and provide some key considerations when choosing a manufacturer for your business.

The Origins of ECCO (Danish Roots)

ECCO began in 1963 when Karl and Birte Toosbuy sold their home and moved to Bredebro, Denmark, to pursue their dream of starting a shoe factory.

What began as a small family business has grown into a global footwear brand known for quality, innovation, and comfort.

From the start, ECCO focused on Danish craftsmanship, premium leather, and designs that follow the natural shape of the foot.

Staying family-owned has allowed the company to prioritize long-term values, treating employees as part of the ECCO “family” and maintaining a culture of collaboration, passion, and quality.

Key facts about ECCO:

- Founded in 1963 by Karl Toosbuy in Denmark

- Family-owned business with a global presence

- Known for premium materials and innovative comfort technology

Where Are ECCO Shoes Made?

Today, ECCO shoes are a truly global product. Unlike most footwear brands, ECCO owns and operates nearly all of its factories, producing around 98% of its shoes in company-owned facilities. This level of control is rare in the industry and ensures consistent quality across markets.

Almost 98% of ECCO’s production now lies in Portugal, Thailand, Indonesia, Vietnam, and China, with only a small percentage made elsewhere under license (such as limited runs in India).

Denmark, once the brand’s sole manufacturing site for its first two decades, no longer produces ECCO shoes at scale. Instead, Bredebro remains home to ECCO’s headquarters and design teams, while large-scale manufacturing takes place in these global hubs.

Let’s look at the main countries where its shoes are produced today. Each factory plays a unique role in the company’s growth and quality control strategy.

Portugal (Europe)

ECCO opened a factory in Portugal in 1984, which became a major production hub with over 1,200 employees and advanced robotics for shoemaking. This facility still produces a large volume of ECCO shoes today, and also hosts ECCO’s R&D center since 2009.

Indonesia (Asia)

ECCO’s first Asian factory opened in 1990 in Indonesia. This site grew to become one of ECCO’s largest facilities, nearly 8,000 workers, complete with a leather beamhouse (for initial hide processing) and later a full tannery on-site.

Thailand (Asia)

ECCO set up a factory in Ayutthaya, Thailand in 1993, which today employs over 3,000 people. A tannery was added in 1999, underlining ECCO’s strategy of making leather in-house wherever it has shoe production.

China (Asia)

In 2005, ECCO began manufacturing in China as well, recognizing the country’s central role in footwear production. A tannery in Xiamen, China followed in 2008. The China facilities employ around 3,500 workers and produce a significant share of ECCO’s output.

Vietnam (Asia)

The newest ECCO factory opened in 2015–2016 in Vietnam. After a trial period, it ramped up to full production and added further capacity in Asia. Vietnam’s growing skilled workforce and shoe industry make it a fitting addition to ECCO’s network.

Slovakia (Europe)

In 1998, ECCO established a factory in Martin, Slovakia, which produced tens of millions of pairs over nearly three decades. (As of 2025, ECCO announced this Slovak factory will be shut down amid global restructuring, consolidating European production elsewhere.)

Why ECCO Owns Its Factories

One thing that sets ECCO apart in the shoe industry is its commitment to owning its entire production chain. Most footwear brands outsource manufacturing to third-party factories, but ECCO chooses a different path: vertical integration. Here’s why:

Full Control From Start to Finish

Most shoe brands outsource production, but ECCO does things differently. The company owns its tanneries and factories, which means it controls everything from leather to finished shoes. This approach costs more to run, but it keeps standards high and consistent.

Room to Innovate

Because ECCO makes its own shoes, it can test and roll out new ideas quickly. The company was one of the first to use CAD/CAM technology in the 1970s and later brought in robotics to improve precision. Without third-party factories slowing things down, ECCO can protect its methods and introduce improvements faster than many competitors.

Owning the Leather Supply

Leather is at the heart of ECCO shoes, so the company also owns tanneries in the Netherlands, Thailand, Indonesia, and China. By doing this, ECCO ensures a steady supply of high-quality leather and avoids relying on outside suppliers. The leather division has grown so much that it even supplies other luxury brands. Keeping tanning and shoemaking close together also saves time and cost.

Setting Standards

Running its own factories gives ECCO more control over working conditions and sustainability. Instead of leaving it up to subcontractors, ECCO can apply the same standards across all its sites. This helps the company stay true to its values of quality, responsibility, and long-term focus.

ECCO’s Shoe Manufacturing Process and Quality Control

ECCO’s production isn’t just about making shoes, it’s about combining craftsmanship with cutting-edge technology under one roof.

By keeping control of the entire process, the company ensures every pair meets the same high standards, no matter where it’s made.

Here are the key elements that define ECCO’s approach:

- Direct Injection Process (DIP): ECCO pioneered DIP to attach soles. Instead of glue, liquid polyurethane is injected into a mold around the upper, bonding the sole directly. This makes shoes lighter, stronger, and more comfortable, with fewer pressure points and almost no risk of soles peeling off. Today, most ECCO shoes use this method.

- Strict Quality Control: Every step of production is monitored. ECCO’s tanneries deliver leather to exact standards of thickness, color, and durability. Factories use robotics and precision machinery for cutting and assembly, while inspectors check shoes after molding, stitching, and finishing. This ensures consistency across factories worldwide.

- Craftsmanship + Training: Skilled workers still play a central role. Stitching, finishing, and detailing are handled by trained artisans. ECCO runs training programs to keep standards consistent whether a shoe is made in Portugal, Thailand, or Vietnam.

- Global Quality System: Owning its factories means ECCO applies the same quality system everywhere. Even when issues arise, like a batch of polyurethane soles that degraded in the late 1990s, ECCO could quickly identify and fix the problem across all sites.

- Innovation and R&D: ECCO continuously improves processes at its research centers in Denmark and Portugal. Recent advances include using 3D printing for sole molds, cutting prototyping time from weeks to days. By the time a shoe design reaches mass production, it has already been refined through multiple iterations.

In short, ECCO combines advanced engineering, premium materials, and skilled craftsmanship. This control from hide to finished shoe is what gives the brand its reputation for durability and comfort, and offers entrepreneurs a clear example of how strong processes build strong products.

If you also want to learn from the manufacturing process of other popular brands, here’s a list to gain some inspiration:

Read more:

- Where Are Asics Made

- Where Are Hoka Shoes Made

- Where Are Keen Shoes Made

- Where Are Van Shoes Made

- Where are Nike Shoes Made

- Where Are Adidas Made

- Where Are Salomon Shoes Made

- Where Are Puma Shoes Made

Key Considerations When Choosing a Shoe Manufacturer

When selecting a shoe manufacturer for your eCommerce business, consider the following elements to make an informed decision.

1. Supply Chain Reliability

It is crucial to choose a manufacturer with a reliable supply chain.

This ensures consistent delivery of materials, timely manufacturing, and order fulfillment.

Research a manufacturer’s track record, look for existing partnerships, and gather testimonials, if possible, to gauge their reliability.

2. Cost Implications

Understanding the cost structure of a shoe manufacturer is vital for maintaining your profit margin.

Analyze factors such as material costs, labor expenses, shipping fees, and other hidden charges. You may also want to investigate the possibility of volume discounts or other incentives offered by a manufacturer.

3. Product Availability

Make sure the manufacturer meets the demand for your store.

For example, ECCO shoes are made in various countries like Portugal, Thailand, China, and Vietnam. Each country contributes to different parts of the production process.

It is essential to assess the lead time, the available stock, and the manufacturer’s ability to replenish the inventory when required.

4. Quality Control

Quality is a key selling point for shoes like ECCO.

It’s important to collaborate with a manufacturer that guarantees quality control across all stages of production.

Investigate whether they have a dedicated quality assurance team and the measures they take to ensure consistent product quality.

5. Environmental and Ethical Considerations

Today, consumers are increasingly conscious of ethical and environmental issues.

Align yourself with a manufacturer who adheres to environmental and ethical standards, like leather sourced from tanneries in Portugal and China.

Examine their practices regarding fair wages, safe working conditions, and sustainable manufacturing methods.

Frequently Asked Questions

Are Ecco Shoes Still Made in Denmark?

Originally, yes. For the first two decades, all ECCO shoes were made in Bredebro, Denmark, the site of the company’s very first factory. But as demand grew, production moved abroad.

Today, ECCO’s large-scale manufacturing takes place in its factories in Portugal, Slovakia (until its closure in 2025), Indonesia, Thailand, China, and Vietnam. Denmark is no longer a production hub for commercial footwear, though it still serves as ECCO’s headquarters and design center.

Some prototyping and R&D work may still happen there, but the shoes you find in stores are made in ECCO’s global factories.

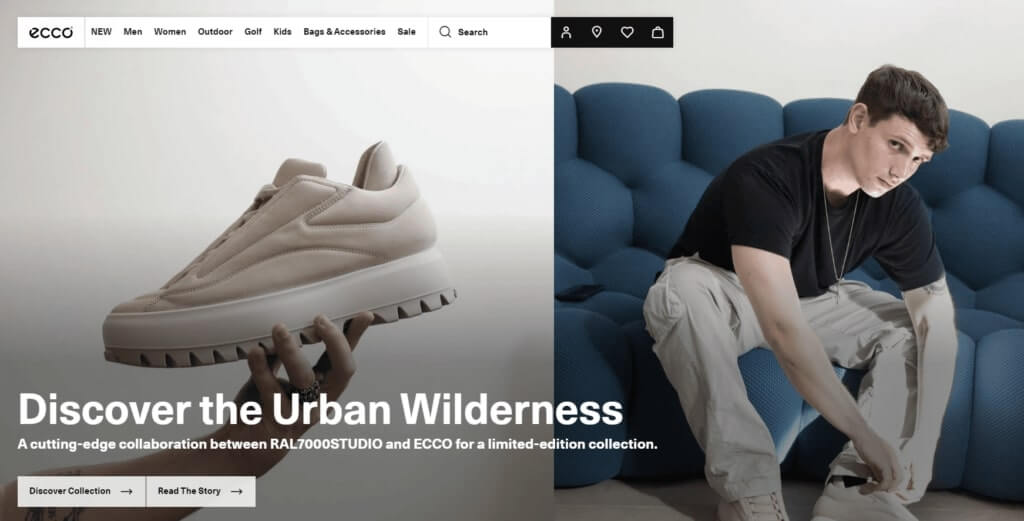

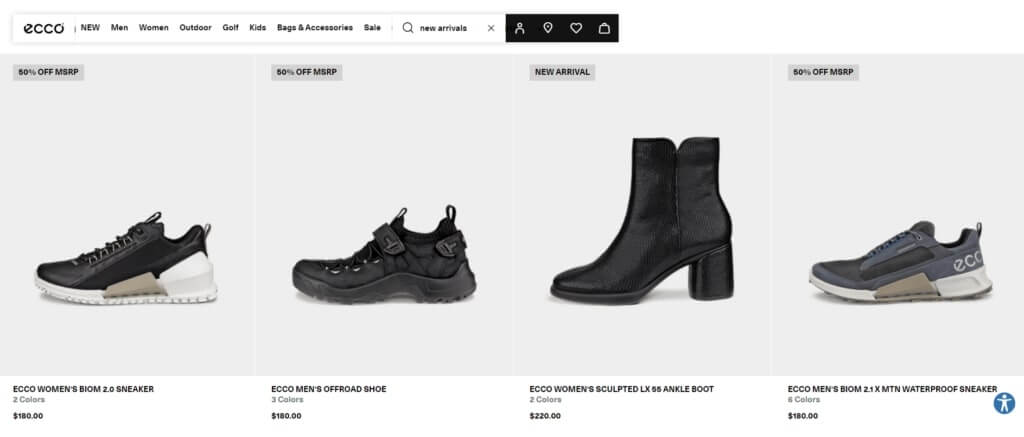

What Types of Shoes Does ECCO Specialize In?

ECCO specializes in a wide range of footwear, catering to various needs and styles. In their collection, you’ll find stylish sandals, casual slip-ons, boots, and business-casual shoes. They offer comfortable and durable options for both men and women.

Are ECCO Shoes Good Quality?

Yes, ECCO shoes are known for their good quality.

The company owns tanneries and factories in various countries, including China, Thailand, Vietnam, Indonesia, Slovakia, and Portugal, ensuring high-quality production and materials.

ECCO’s commitment to quality and comfort makes them a popular choice among consumers worldwide.

Are ECCO Shoes Known for Being Ethically Produced?

While we cannot specifically mention their ethical production standards, it is worth noting that ECCO owns their tanneries and factories.

This allows them greater control over the production process, materials sourcing, and treatment of workers, which suggests that they prioritize responsible and ethical manufacturing practices.

What Sets ECCO Shoes Apart from Other Brands in the Market?

ECCO shoes stand out for their blend of style, comfort, and durability. They cater to a wide variety of customers and shoe preferences.

The company’s commitment to owning their factories and tanneries allows for better quality control and fosters innovation in design and materials.

What Are Some of the Best Shoe Manufacturers in China?

China is home to numerous shoe manufacturers. If you’re looking for a reliable supplier, you can refer to this list of top 14 shoe manufacturers in China to help you make an informed decision and source your shoes effectively.

Work with a Reliable Shoe Manufacturer with Niche

ECCO shoes are manufactured in different locations worldwide, with a significant portion of production taking place in China. As a seller, it’s important to consider the manufacturing country as it can impact quality, production costs, and logistics.

China is a popular choice for many brands when it comes to outsourcing production due to its cost-effectiveness, skilled workforce, and well-established infrastructure.

When you’re planning your shoe business, partnering with a reliable manufacturer in China can be a game-changer for your profit margins and overall success.

This is how working with a sourcing agent like NicheSources can make a difference in finding the right manufacturer for your needs.

We help streamline the process, ensuring that you’re connected with manufacturers who can deliver quality products on time and within your budget.

So, if you’re considering following ECCO’s footsteps and working with a Chinese manufacturer for your shoe line, don’t hesitate to request a free sourcing quote from us at NicheSources.

We’ll help you find the perfect partner to bring your shoe designs to life and ensure a smooth production process for your business.