Keen is a well-known footwear brand, especially popular among outdoor enthusiasts and adventure seekers. If you’re a seller looking for reliable shoe suppliers, knowing where Keen shoes are made can help you make smarter sourcing decisions.

Keen manufactures its shoes in multiple countries, including the United States, China, Vietnam, Cambodia, India, Japan, Thailand, Romania, and Mexico.

But what does this mean for quality, pricing, and supply chain reliability?

In this guide, we’ll take a closer look at Keen’s manufacturing locations, the factories behind the brand, and key factors to consider when choosing the right shoe supplier for your business.

Where Are Keen Shoes Made?

Keen manufactures its shoes across multiple countries, to balance quality, cost-efficiency, and market accessibility.

Their production spans the United States, China, Vietnam, Cambodia, India, Thailand, Japan, Romania, and Mexico, with each facility chosen for its strategic advantages. Let’s discuss the role of each facility in more detail.

United States: Portland, Oregon

Keen operates a footwear factory in Portland, Oregon, just minutes from its headquarters. This facility produces the American Built collection, a lineup of boots and work shoes assembled in the U.S. using globally sourced materials. By manufacturing in the U.S., Keen maintains close oversight on quality while supporting local workers.

China, Vietnam, and Cambodia: Leading Footwear Hubs

A significant portion of Keen’s footwear is made in China, Vietnam, and Cambodia, regions known for their strong shoe manufacturing infrastructure. Many global footwear brands rely on these countries due to their:

- Skilled workforce with decades of experience.

- Cost-effective production compared to Western countries.

- Advanced manufacturing capabilities for high-quality output.

India and Thailand: Expanding Production Capacity

Keen also manufactures in India and Thailand, leveraging their well-established shoe industries. These locations help the brand diversify its supply chain while maintaining production efficiency.

Mexico: Nearshore Manufacturing for U.S. Distribution

Keen’s production facilities in Mexico play a strategic role in supplying the North American market. Mexico’s skilled workforce and proximity to the U.S. help reduce shipping costs and delivery times, making it a key part of Keen’s supply network.

Romania: European Manufacturing for Regional Markets

Keen’s European production is based in Romania, allowing the brand to cater to European customers more efficiently. This regional presence helps Keen meet local demand while reducing shipping distances and import-related costs.

Why Does Keen Manufacture in Different Countries?

If you’ve ever wondered why Keen shoes come from so many different places, the answer is simple: it’s all about quality, cost, and getting products to customers faster.

Manufacturing in multiple countries helps Keen balance these factors while staying competitive in the global footwear market.

1. Keeping Quality in Check

Keen isn’t just about mass-producing shoes—they care about quality. That’s why they make their American Built collection in the U.S., where they can keep a close eye on the process.

But they also work with experienced factories in China, Vietnam, and Thailand, where skilled shoemakers ensure that every pair meets Keen’s standards.

2. Making Shoes More Affordable

Let’s be real—making everything in the U.S. would drive prices way up. That’s why Keen manufacturers in Asia, where production costs are lower. Countries like China, Vietnam, and Cambodia have well-established footwear industries, helping Keen create high-quality shoes without breaking the bank.

3. Avoiding Supply Chain Headaches

If there’s one thing brands have learned in recent years, it’s that relying on a single country for production can be risky.

Tariffs, factory shutdowns, and shipping delays can all cause major disruptions.

By spreading production across multiple locations—including Mexico and Romania—Keen keeps things running smoothly no matter what happens.

4. Faster Shipping, Happier Customers

Nobody likes waiting weeks for their order to arrive. By manufacturing closer to major markets like Mexico for the U.S. and Romania for Europe, Keen reduces shipping times and gets shoes to customers faster. This is a huge advantage for both the brand and retailers.

5. Catering to Different Markets

Not all customers want the same thing. Some regions prioritize locally made products, while others care more about price.

Keen’s global manufacturing approach allows them to offer the right products at the right price for different markets.

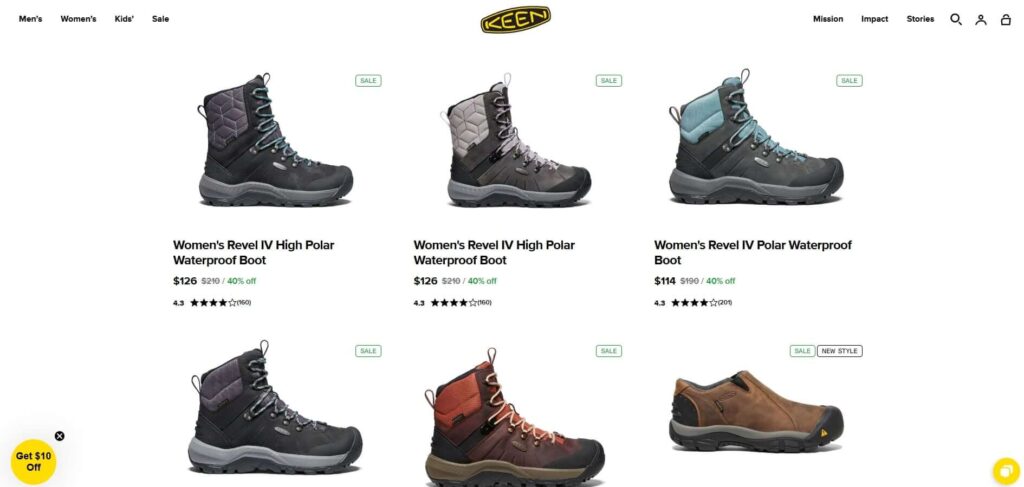

Keen’s Pricing Strategy: Where Do Their Shoes Stand?

Keen shoes fall into the mid-to-premium price range, making them more expensive than budget footwear but generally more affordable than high-end outdoor brands like Merrell or Arc’teryx.

Their pricing reflects a balance between quality, durability, and ethical production practices, which appeal to consumers willing to pay for long-lasting footwear.

How Keen Prices Its Shoes

Several factors influence Keen’s pricing:

- Material & Durability – Keen uses high-quality leather, waterproof membranes, and reinforced toe caps, increasing production costs but offering superior longevity.

- Manufacturing Locations – While some Keen shoes are made in the U.S. (which raises costs), many are produced in China, Vietnam, and Cambodia to keep prices competitive.

- Brand Positioning – Keen markets itself as an outdoor and workwear specialist, justifying higher prices with functionality, comfort, and ethical practices.

On average, Keen shoes range from $100 to $200, with their work boots and American-made styles on the higher end.

What Sellers Can Learn from Keen’s Pricing

For shoe sellers looking to source and price their own footwear, Keen’s strategy offers a few key takeaways:

- Customers Will Pay for Quality – Keen’s buyers prioritize durability and function over just price. If you’re sourcing footwear, consider whether your market values long-lasting materials or budget-friendly options.

- Ethical & Sustainable Practices Justify Higher Prices – Keen highlights its use of responsible manufacturing, which many consumers are willing to pay extra for. Exploring eco-friendly materials or fair-trade factories can be a unique selling point.

- Branding & Specialization Matter – Keen targets outdoor enthusiasts and workers, allowing them to charge more. Sellers can find a niche and tailor their pricing accordingly.

Competing with Keen: Is There Room for Budget-Friendly Alternatives?

While Keen dominates the mid-range market, not every customer wants to spend over $100 on shoes. This opens opportunities for sellers to:

- Offer affordable alternatives with similar features but lower production costs.

- Find Chinese manufacturers (more on this later) who can produce functional, stylish outdoor footwear at a fraction of the price.

- Create a private-label brand with competitive pricing while emphasizing unique selling points.

Understanding Keen’s pricing strategy helps sellers make smarter sourcing decisions and position their products effectively in the market.

Behind the Scenes: Keen’s Factories and Manufacturing Process

Keen’s production takes place in multiple countries, including the United States, China, Vietnam, Cambodia, India, Japan, Thailand, Romania, and Mexico.

However, not all Keen shoes are outsourced—about one in three pairs come from their own factories in Portland, Dominican Republic, and Thailand. This gives Keen greater control over production quality, labor conditions, and sustainability efforts.

For shoe sellers, understanding the manufacturing process is important when sourcing products. Keen’s process involves several key steps that contribute to the durability and comfort the brand is known for.

From Design to Production

It all starts with design and material selection. Keen focuses on rugged, outdoor-ready construction, using materials like high-traction rubber, waterproof leather, and breathable mesh. Once the designs are finalized, factories source these materials from trusted suppliers.

Precision in Assembly and Construction

The actual production process involves several key stages:

- Material Cutting & Stitching: Skilled workers cut fabrics, leather, and synthetic materials before assembling the shoe’s upper.

- Outsole Attachment (Vulcanization): Keen uses heat and pressure to bond the rubber outsole to the upper, a process that enhances durability and flexibility.

- Hand Finishing & Detailing: Unlike mass-produced shoes that rely solely on automation, Keen incorporates handcrafted elements to ensure a more precise fit.

Stringent Quality Control

Quality control is a crucial aspect of the Keen manufacturing process. Each shoe undergoes a thorough inspection to ensure that it meets the company’s high standards. This includes checking for proper sizing, consistent stitching, and overall appearance.

What Sellers Can Learn from Keen’s Manufacturing Approach

Keen’s strategy highlights the importance of balancing cost, quality, and branding. Their combination of in-house production and outsourced manufacturing allows them to maintain high standards while optimizing costs.

For sellers, this presents a valuable lesson: sourcing from reputable manufacturers that prioritize quality control and material selection can help build a strong brand.

Whether through private labeling or custom designs, working with factories that follow structured production processes—like Keen’s—can lead to higher customer satisfaction and fewer product returns.

How Chinese Manufacturers Can Help You Compete with Keen

If you’re looking to sell outdoor or workwear-style footwear, sourcing from Chinese manufacturers can be a cost-effective way to compete with brands like Keen.

China is one of the world’s largest footwear producers, offering a combination of affordable pricing, customization options, and scalable production.

Cost Effective Production

Keen’s mid-to-premium pricing comes from its focus on durability and functionality. The good news? Chinese factories can achieve similar quality at a fraction of the cost.

Many manufacturers specialize in sturdy materials like reinforced rubber soles, waterproof membranes, and breathable fabrics. Some even use the same production techniques found in global brands, ensuring durability without the premium price tag.

By working directly with factories, sellers can access rugged, high-performance shoes that appeal to outdoor enthusiasts and workers—without breaking their budget.

Customization for Private Label Brands

Many Chinese factories allow you to customize designs, materials, and branding, which means you can create a product tailored to your target audience. Private labeling gives you control over:

- Logos and branding – You can sell under your own brand instead of reselling existing products.

- Unique features – Want waterproof hiking boots or lightweight work shoes? Chinese manufacturers can tailor materials to your needs.

- Pricing strategy – By managing costs, you can price your products competitively while maintaining good profit margins.

Scalable & Flexible Manufacturing

Unlike Keen, which relies on multiple countries for production, many Chinese factories handle everything in-house, making the supply chain more efficient and flexible. This allows for:

- Small MOQs – Ideal for new sellers testing the market.

- Mass Production – If demand grows, manufacturers can quickly scale up production.

- Faster Turnaround Times – Many Chinese suppliers can manufacture and ship products faster than sourcing from multiple regions.

Flexible & Scalable Manufacturing

One of the biggest advantages of working with Chinese manufacturers is the ability to scale production.

Unlike Keen, which spreads its supply chain across multiple countries, many Chinese suppliers offer end-to-end production under one roof. This makes it easier to test small batches before committing to larger orders.

For new sellers, this means lower risk and faster turnaround times. You can start with a small quantity, test the market, and increase orders as demand grows.

Once you gain traction, manufacturers can quickly ramp up production, making sure you never run out of stock.

If you want to learn more from the success of other brands like Keen then check out our reading list below:

Read More:

- Where Are Salomon Shoes Made

- Where Are Adidas Made

- Where Are Nike Shoes Made

- Where Are Asics Made

- Where Are Puma Shoes Made

How to Choose the Right Shoes Supplier?

When selecting a Chinese shoes supplier for your business, there are several factors to consider.. Let’s discuss some essential aspects to help you make an informed decision.

1. Product Quality

High-quality products are crucial for maintaining customer satisfaction and attracting repeat buyers. Examine samples and check for construction, material, and overall durability before committing to a supplier.

2. Manufacturing Locations

Keen shoes are made in various countries, such as the United States, China, Vietnam, Cambodia, India, Japan, Thailand, Romania, and Mexico. Consider location when choosing a supplier, as it may impact shipping times, costs, and ease of communication.

3. Supplier Reputation

Research potential suppliers’ backgrounds to ensure they have a reliable track record. Look for testimonials, reviews, or case studies from other businesses to gauge their professionalism and dependability.

4. Product Range and Variety

A diverse product offering is essential for meeting the various needs of your customers. Ensure the supplier offers a wide range of styles, colors, and sizes to cater to different preferences.

5. Minimum Order Quantities (MOQs)

Smaller MOQs allow you to test the market without committing to large stock volumes. Compare suppliers’ MOQs and choose one that aligns with your business’s initial needs and capacity to scale.

6. Pricing and Terms

Analyze different suppliers’ pricing structures to find a balance between cost and quality. Negotiate favorable payment terms that match your business’s cash flow and budget.

7. Ethical Sourcing and Sustainability

Today, customers care about ethically manufactured products and environmental responsibility. Ensure your supplier adheres to ethical sourcing practices and has sustainable production methods in place.

8. Communication and Responsiveness

A strong partnership necessitates open and timely communication. Gauge how quickly potential suppliers respond to your inquiries, and assess their willingness to collaborate on specific requests or modifications.

9. Lead Times and Timely Delivery

Delays can hurt your business, resulting in lost sales and customer dissatisfaction. Understand the suppliers’ lead times and their ability to deliver products on schedule.

10. Return and Refund Policies

Familiarize yourself with suppliers’ return and refund policies to know how they handle defective products, overstocked items, or incorrect shipments. A flexible and comprehensive policy helps safeguard your business’s reputation and profitability.

Frequently Asked Questions

Is Keen a Good Brand of Shoes?

Yes, Keen is considered a good brand of shoes. They are known for their quality, durability, and comfort. The brand has a strong commitment to producing innovative designs and protecting the environment.

What Types of Shoes Does Keen Offer?

Keen offers a wide variety of shoe types, including sandals, hiking boots, casual shoes, and work boots. They cater to men, women, and children, ensuring that everyone can find a comfortable and functional pair of Keen shoes for their needs.

Why Are Keens So Comfortable?

Keens are often praised for their comfort because they have a roomy toe box, cushioned insoles, and supportive footbeds.

These features allow the wearer to have ample space for their toes and provide proper arch support, giving them long-lasting comfort even during extended periods of wear.

How Do Keen Shoes for Men and Women Differ?

Keen shoes for men and women are designed with the specific needs of each gender in mind.

Men’s shoes tend to be wider, while women’s shoes are generally narrower. Additionally, women’s shoes may have a slightly higher arch to cater to their feet’s unique shape and needs.

Overall, both men’s and women’s Keen shoes offer the same high-quality materials and designs.

What Are Some of the Best Shoe Manufacturers in China?

There are numerous reputable shoe manufacturers in China that cater to various types and styles of footwear.

This list of the top 14 shoe manufacturers in China is a great starting point, providing insights into some of the leading shoe suppliers in the country.

These manufacturers are known for their vast range of products and commitment to quality, making them ideal partners for shoe sellers looking to expand their business.

Finding the Right Shoes Supplier: A Recap

Keen’s manufacturing strategy is a great example of how brands can balance cost, quality, and efficiency by producing shoes in multiple countries.

While they do have a U.S. factory, most of their production happens in China, Vietnam, and other major manufacturing hubs—and for good reason.

These regions offer skilled labor, large-scale production, and competitive pricing, which is why so many global brands rely on them.

If you’re a shoe seller, there’s a lot to learn from this approach. Working with the right supplier can make all the difference, whether you’re looking for affordability, customization, or quality materials.

But let’s be real, sourcing from overseas isn’t always easy. Finding trustworthy manufacturers, ensuring product quality, and negotiating good terms can be a challenge.

That’s where NicheSources comes in. We help sellers like you connect with reliable Chinese manufacturers, handle quality control, and get the best deals. Ready to find the right shoe supplier? Request a free quote today and let’s get started!