Ninja is one of the most popular kitchen appliance brands out there, from blenders and air fryers to coffee makers and more.

But where Ninja products are actually made?

The answer isn’t just one country. Over the years, Ninja’s manufacturing locations have changed, and there’s a good reason behind it.

In this article, we’ll cover everything about Ninja products including where they’re made and the current status of the company.

Key Takeaways

- As of early 2026, nearly all Ninja products sold in the U.S. are made in Southeast Asia, like Vietnam, Thailand, Malaysia, Indonesia, and Cambodia.

- The shift happened because U.S. tariffs made China more expensive, and by the end of 2025, production for U.S. markets was almost fully moved.

- For other markets (like Europe or Asia), many products still come from China, plus key parts for everywhere.

- SharkNinja, the parent company, focuses on a smart global setup to stay efficient and innovative.

Who Owns Ninja?

Ninja is a household name in the world of blenders, air fryers, and other small kitchen appliances, but who actually owns the brand?

It’s owned by SharkNinja, Inc., based in Needham, Massachusetts, USA. The brand is American at heart, with design and bosses there, but it’s had some international owners before.

Here’s a quick history:

- In 2017, it was bought by JS Global Lifestyle, a Chinese group that owns Joyoung. This helped with better factories, per SharkNinja’s Wikipedia page.

- In July 2023, SharkNinja split off and went public on the NYSE (ticker: SN)

- The spin-off marked SharkNinja’s return as a standalone American brand, though it still maintains a global supply chain.

- Today in 2026, it’s fully independent and American-led. CEO Mark Barrocas is pushing to rely less on China while keeping global ties. Design and R&D are still in the U.S.

So yes, Ninja is an American company, both in its origins and current structure, even though it previously operated under Chinese ownership and still partners with overseas manufacturers for production.

Where Are Ninja Products Made?

Flip over a new Ninja blender or air fryer for the U.S., and you probably won’t see “Made in China.” By early 2026, most U.S. production has moved to Southeast Asia to dodge high costs.

Why the Big Shift?

Back in 2018, U.S. tariffs hit Chinese imports hard. That made making things in China too pricey for the U.S. market. So SharkNinja started moving:

- By mid-2025, about 90% of U.S. stuff was out of China

- By the end of 2025 (and into 2026), it’s nearly 100% for U.S. products, from Bloomberg’s interview with the CEO.

Where Are They Made Now (as of 2026)?

Most Ninja gadgets, like air fryers and blenders, are put together in Southeast Asia:

- Vietnam: Top spot for U.S. items, with good workers and trade deals.

- Thailand: Great for electronics and quick supply.

- Malaysia: Handles high-tech parts and assembly.

- Indonesia: Growing fast for cheap production

- Cambodia: Good for hands-on work.

Why those countries?

Because they checked all the right boxes:

- Lower labor costs

- Growing manufacturing hubs

- Favorable trade terms with the U.S.

- A lot of existing expertise in making appliances and electronics

And in many cases, the same manufacturers Ninja worked with in China simply moved their operations to nearby countries. So while the location changed, the production quality and processes stayed consistent.

Want a visual? Check a map of Southeast Asia manufacturing spots on Google Maps: Southeast Asia Manufacturing Map.

Why Not Just Make Ninja Products in the U.S.?

The answer’s simple: the U.S. doesn’t have the right supply chain for this kind of manufacturing.

In fact, SharkNinja’s CEO, Mark Barrocas, said it bluntly:

“There’s no supply chain for U.S.-made blenders.”

Unlike Southeast Asia, the U.S. lacks the factory ecosystem needed to source parts like motors, heating elements, and plastic molds, all the little things that make appliances tick.

So even though Ninja is very much an American brand, overseas production still makes the most sense.

Were Ninja Products Made in China?

Yes, for a long time. In the 2010s, most came from well-known manufacturing regions like Shunde in Guangdong, and Cixi or Yuyao in Zhejiang. China was cheap, fast, and advanced.

Even today, China’s involved:

- Many key parts (like motors) come from there.

- Products for non-U.S. markets are still made in China.

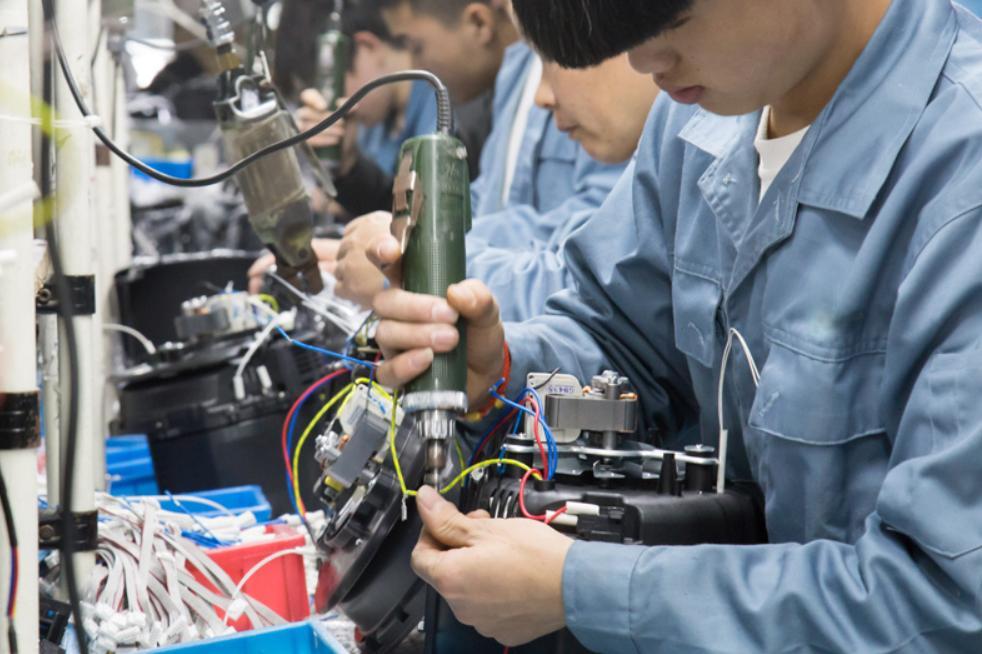

Chinese Factories for Small Appliance Contract Manufacturing

So Ninja may have shifted most of its production out of China, but that doesn’t mean China’s out of the game. In fact, if you’re in the business of sourcing air fryers, blenders, or kitchen gadgets, China is still the global powerhouse when it comes to small appliance manufacturing.

Let’s take a closer look.

China Still Runs the Show for OEM & ODM

Even though final assembly for Ninja products now happens in Southeast Asia, many key components are still sourced from China, and for good reason.

China’s appliance industry has had a head start for decades. It’s packed with:

- Highly specialized factories

- Advanced tooling and automation

- Efficient supply chains

- Skilled labor with deep category experience

Regions like Guangdong and Zhejiang have entire cities built around appliance production. You can find world-class OEM/ODM factories that don’t just build appliances, they help design and customize them, too.

Even if Ninja isn’t assembling products in these cities anymore, you’ll find factories that produce for other major global brands, and they’re open for business.

| Factory Name | Location | Known For | Notable Clients |

| Yuyao Biyi Appliances | Zhejiang | Air fryers, small kitchen appliances | Ninja, Philips, Newell |

| Xinbao (Donlim) | Guangdong | Coffee makers, kettles, air fryers | Electrolux, Panasonic, Conair |

| Cixi Jiale Intelligent Tech | Zhejiang | Air fryers (global leader) | Xiaomi, Joyoung, Panasonic |

| Boling Electrical | Ningbo | Blenders, juicers, upscale appliances | Nutribullet, Bosch, SEB |

Fun fact: Yuyao Biyi was once linked to Ninja’s air fryer production before the brand shifted operations.

Benefits of Sourcing from Chinese Factories

Even though brands like Ninja are shifting final assembly out of China, the country is still the undisputed king of small appliance sourcing, and for good reason.

1. Cost-Effective (Without Cutting Corners)

Let’s start with the obvious: China is still one of the most cost-efficient places to make things, especially at scale.

Why? Because factories here benefit from:

- Decades of process optimization

- Huge production volumes (aka economies of scale)

- Tight supplier networks that reduce logistics costs

The result? You get more for less, without having to compromise on quality.

2. A Fully Built-Out Supply Chain

In places like Shunde or Cixi, factories don’t have to wait weeks for parts to arrive from another country, they can get motors, circuit boards, plastic molds, packaging, and tooling all within a few miles.

That means:

- Faster production times

- Lower shipping costs

- Easier scaling when your order size grows

For you, that translates to smoother operations and fewer delays.

3. OEM & ODM Flexibility

Need your own branding on the product? Want to tweak a design or create something new from scratch?

Chinese factories are incredibly flexible when it comes to customization. Most offer:

- OEM (your brand on their existing product)

- ODM (custom product built from your specs)

Whether you’re starting a niche appliance brand or building a product line for retail, they’ll usually work with you on mold development, packaging, and even user manuals.

4. Serious Manufacturing Experience

We’re not talking about trial-and-error workshops here. These are seasoned factories that have:

- Produced for brands like Philips, Panasonic, Hamilton Beach, and Ninja

- Built millions of units annually

- Mastered strict quality standards (ISO, CE, UL, RoHS, etc.)

In short: you’re working with pros.

5. Competitive Shipping & Export Infrastructure

China has a well-oiled export machine, from factory to port to container ship.

Ports like Ningbo and Shenzhen handle massive daily volumes and are connected to global trade lanes, which means:

- Predictable lead times

- Competitive freight rates

- Fewer customs headaches

6. Fast Iteration & Trend Responsiveness

China is known for its speed. If a new trend pops up, Chinese factories can prototype, test, and start producing faster than most countries can schedule a meeting.

This kind of agility is a major plus if you’re trying to launch fast or ride a seasonal wave.

Quality Assurance in Cross-Border Manufacturing

Manufacturing overseas can raise a few eyebrows, especially when it comes to quality.

But brands like Ninja show that with the right systems in place, you can produce high-quality products even from thousands of miles away.

Here’s how to keep quality in check when sourcing internationally:

- Be specific with your specs: List out materials, motor power, dimensions, safety features, the more detailed, the better.

- Work with certified factories: Look for ISO 9001, CE, UL, or RoHS certifications to ensure they meet global standards.

- Use third-party inspections: Hire local QA teams to check products during and after production.

- Set clear AQL limits: Agree on how many defects (if any) are acceptable before a shipment is rejected.

- Start with samples and pilot runs: Always test a small batch before committing to full-scale production.

- Stay in touch throughout the process: Regular check-ins = fewer surprises and better results.

Final Thoughts

Manufacturing is no longer tied to one country. It’s global, strategic, and constantly evolving.

While Ninja now assembles most of its products in Southeast Asia, China remains a major player in small appliance sourcing, especially when it comes to OEM/ODM opportunities, component quality, and manufacturing speed.

Whether you’re building your own appliance brand or looking for trusted factories to scale production, it’s all about finding the right partner, one that can deliver quality, speed, and flexibility without breaking your budget.

At NicheSources, we connect you with vetted, high-quality manufacturers across China. Whether you’re just starting out or scaling up, we’ll help you find the right factory, negotiate the right deal, and stay in control of quality every step of the way.

Reach out to NicheSources today to find your ideal manufacturing partner.

Want to learn more about how other big brands handle their production? Here’s a list. You’d be surprised to see how many of them outsource production to China in some capacity.