The global backpack market is projected to reach $19.6 billion by 2027, with custom options driving significant growth. Custom backpacks offer businesses a powerful tool to stand out in a crowded market and provide consumers with personalized products that resonate with their lifestyles and values.

For startups looking to make a splash, established brands aiming to refresh their product lines, or corporations seeking impactful promotional items, custom backpacks present a versatile and attractive option. The key to success lies in partnering with the right manufacturer who can bring your unique vision to life.

This guide spotlights the top 12+ custom backpack manufacturers across Asia, America, and Britain, listed in no particular order. We’ve scoured the globe, from high-tech facilities in China to artisanal workshops in the UK, to bring you the cream of the crop.

A List of Custom Backpack Manufacturers

These manufacturers cater to various needs and styles. Whether you’re looking for urban designs or rugged outdoor packs, you’ll find options here.

You can gain professional insights on some of the popular backpack materials by reading our comprehensive guide, which will help you make informed decisions for your product line.

Remember to consider factors like minimum order quantities, customization options, and lead time when choosing a manufacturer. Don’t hesitate to reach out to multiple companies for quotes and samples.

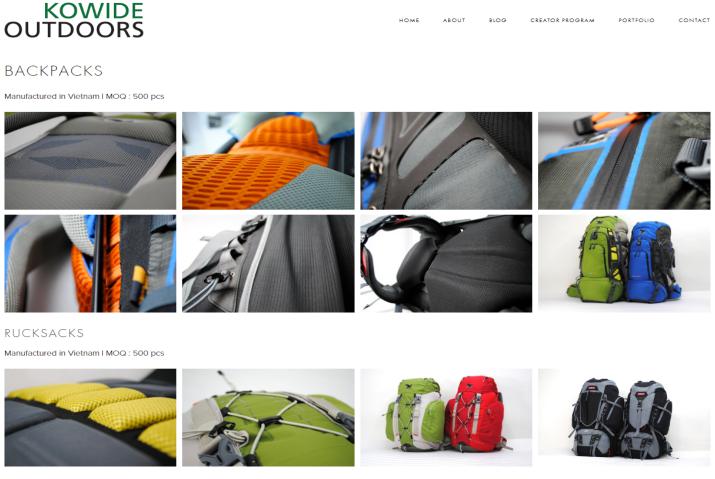

Kowide Outdoors has been crafting custom backpacks and active gear since 1974. They prioritize ethical and sustainable practices in their manufacturing process, ensuring their products align with their brand identity. Their client list includes prestigious automotive brands like Mercedes-Benz and BMW, showcasing their versatility and high standards.

Overview

Location

Kowide Outdoors maintains its headquarters in Taiwan, with an additional office in New York.

Production

The company operates two large production facilities – one in China and another in Vietnam. These factories specialize in manufacturing a wide range of outdoor products, including backpacks, camping equipment, climbing accessories, and apparel.

Services

Kowide Outdoors offers comprehensive services to outdoor and sports brands. They provide design assistance, manufacturing expertise, and branding solutions. This full-service approach allows clients to streamline their product development process.

Key Features

MOQ

Kowide Outdoors has a minimum order quantity (MOQ) of 500 units. This requirement may be suitable for medium to large-scale businesses but could be challenging for smaller brands or startups.

Timelines

You can expect quick turnaround times with Kowide Outdoors. They can produce samples in just 2-3 weeks, allowing you to review and approve designs efficiently. For bulk orders, the typical production time is 6-8 weeks.

Shipping

Kowide Outdoors offers global shipping options.

Quality

Their production facilities in both China and Vietnam are certified for ISO 9001 compliance.

If you're looking to expand your options for backpack suppliers in China, we recommend checking out our comprehensive guide on [20 Outstanding Suppliers of Wholesale Backpacks in China].

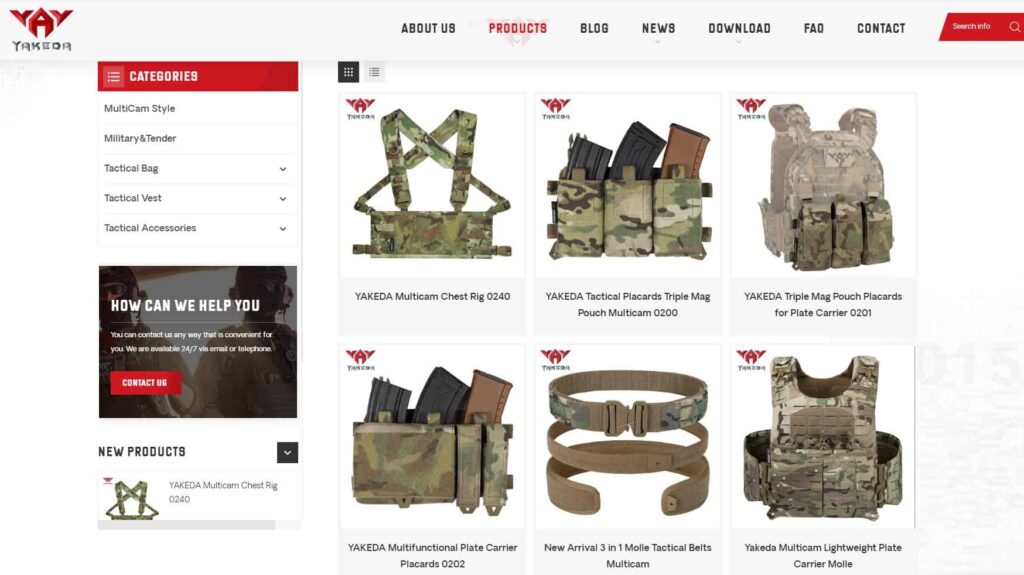

Guangzhou Yakeda Outdoor Travel Products Co., Ltd (China)

Yakeda has been in the tactical equipment business since 2003. They’ve grown significantly, now boasting 68 production lines and over 2,000 workers. Their focus on ODM and OEM orders has paid off, with about 90% of their sales coming from these custom manufacturing services.

Overview

Location

Guangzhou, China.

Production

Yakeda specializes in creating high-quality outdoor and tactical backpacks. Their production capabilities extend to tactical vests, bulletproof vests, chest rigs, and various outdoor equipment. You can even get customized gear tailored to your specific requirements.

Services

Yakeda offers both OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services. This means you can either have them produce your designs or work with their team to develop new products.

Key Features

MOQ

50 units. This lower MOQ makes it easier for smaller businesses or those testing new products to work with them.

Timelines

You can expect sample production in 7-10 days. For bulk orders, they typically ship within 30 days, ensuring you get your products in a timely manner.

Shipping

You have various shipping options available when working with Yakeda. They offer express options for when you need your products quickly.

Quality

They’ve obtained ISO9001 and 14001 certifications.

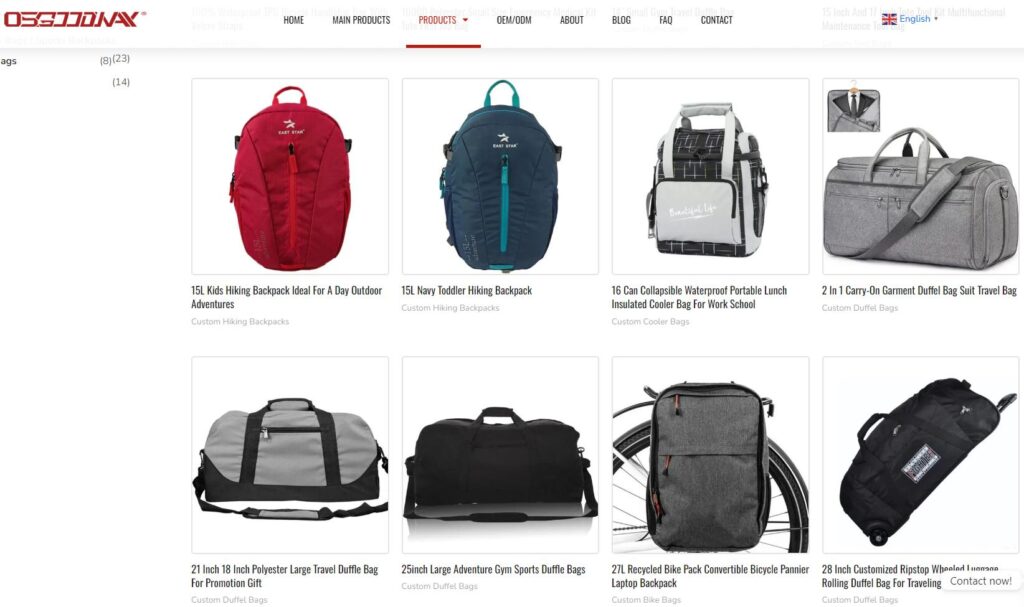

OSGOODWAY (China)

OSGOODWAY is a seasoned custom backpack manufacturer with 18 years of experience. Established in 2006, the company has built a strong reputation in the bag manufacturing industry.

Their products are exported to North America and various European countries, including Germany, the UK, Switzerland, and Norway. The company has collaborated with well-known brands like FILA and American Tourister.

Overview

Location

OSGOODWAY’s manufacturing facility is located in Quanzhou, China. The factory spans an impressive 9,000 square meters and employs between 80-100 skilled workers.

Production

OSGOODWAY produces a diverse range of bag products, including backpacks, car organizers, luggage bags, RPET bags, motorcycle bags, travel bags, tool bags, and sports bags. They also offer custom designs tailored to specific client needs.

Services

The company provides comprehensive OEM services and custom designs for various markets. Their end-to-end supply chain solutions cover everything from product development and raw material sourcing to manufacturing, quality control, and logistics.

Key Features

MOQ

OSGOODWAY doesn’t have a fixed minimum order quantity (MOQ). The MOQ varies depending on the type of bag. For complex backpacks, the minimum order starts at 300 units.

Timelines

You can expect a sample to be ready in 5-7 days. For bulk orders, the typical lead time ranges from 5 to 8 weeks. The exact timeline depends on the complexity and quantity of your order.

Shipping

OSGOODWAY offers multiple shipping options to cater to their international clients.

Quality

They hold several certifications, including:

- BSCI

- Sedex

- ISO9001

- ISO14001

- GRS (Global Recycled Standard)

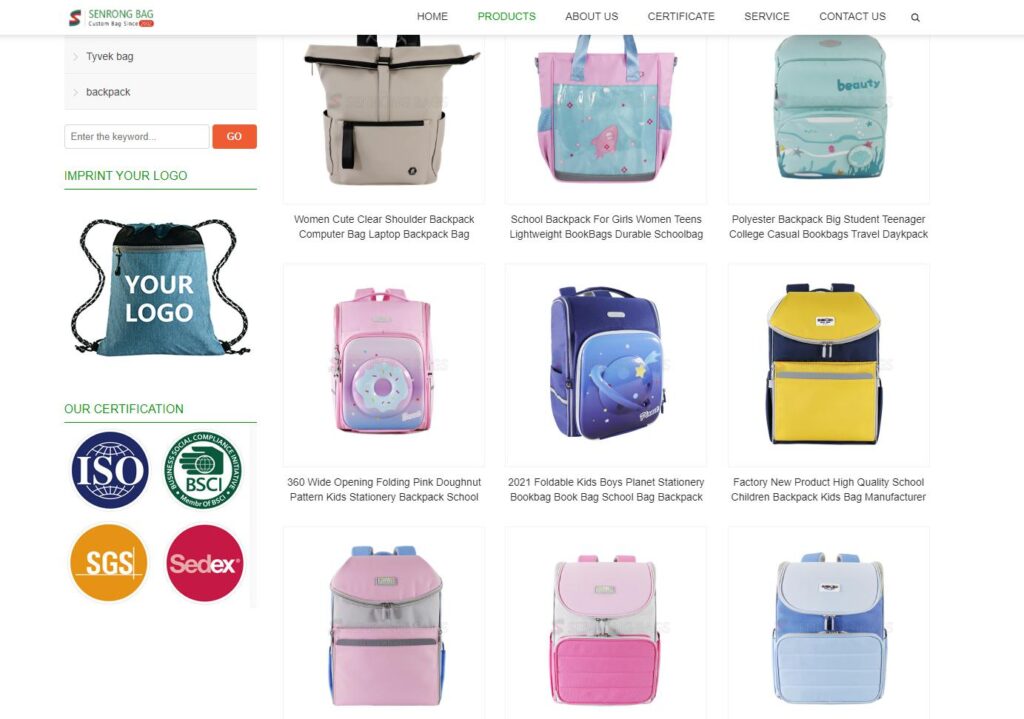

Senrong Bag (Vietnam)

Senrong Bag, operating as SENDA INTERNATIONAL GROUP (HK) LIMITED, brings 17 years of expertise to the table. They specialize in crafting custom backpacks and bags using a variety of materials. Their repertoire includes cotton, canvas, PVC, polyester, and Tyvek.

Overview

Location

Headquarters in Nghia Hung District, Nam Dinh, Vietnam. They’ve also expanded their operations with a factory in Guangzhou, China, giving them a broader production base.

Production

They manufacture a wide array of products, including:

- Cosmetic bags

- Cooler bags

- Luggage covers

- Shopping bags

- Sports bags

Their monthly output can reach up to 4.3 million units, showcasing their ability to handle large-scale orders efficiently.

Services

You can expect both OEM and ODM services from Senrong Bag. They’ve partnered with major international brands, crafting custom bags for names like Nike, Adidas, IKEA, and Watsons.

Key Features

MOQ

Senrong Bag offers flexibility in their minimum order quantities (MOQ). While it varies by product, some items have an MOQ as low as 100 units. This makes them accessible to businesses of various sizes, from startups to established brands.

Timelines

You can expect the following timelines when working with Senrong Bag:

- Sample production: 2-4 weeks

- Bulk orders: 4-6 weeks (may be longer for complex designs)

Shipping

Senrong Bag caters to both domestic and international clients with their shipping options.

Quality

Quality control is a top priority at Senrong Bag. They implement a five-step quality inspection process, covering:

- Sample checks

- Cutting

- Screen printing

- Machine sewing

- Packaging

Their commitment to quality is further validated by successful factory audits from renowned organizations. These include Sedex, SGS, ISO, Coca-Cola, and Disney.

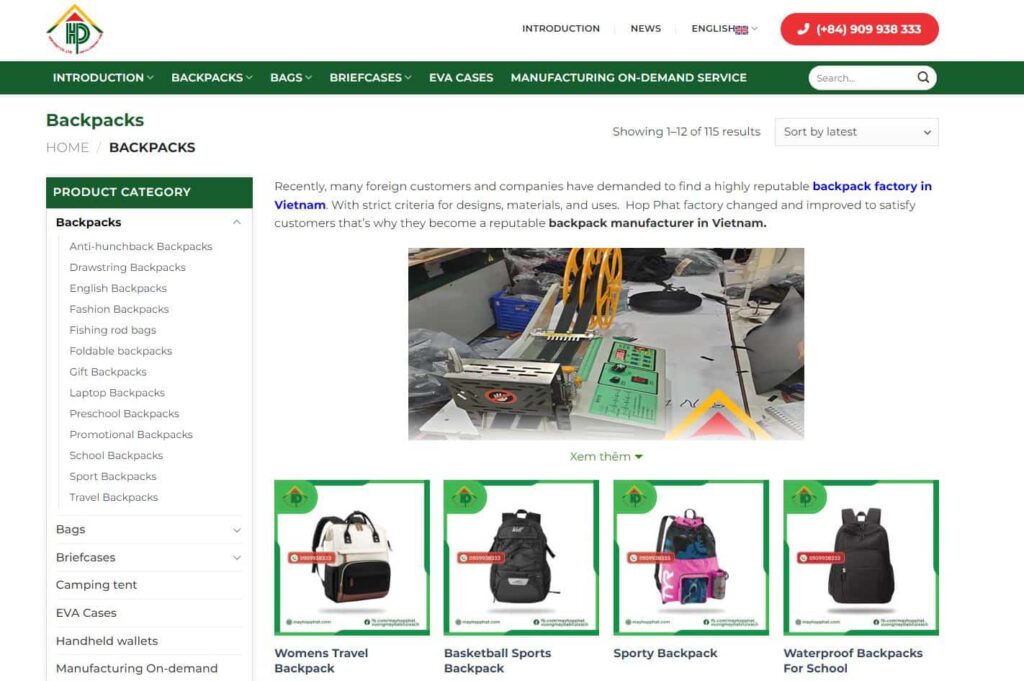

Hop Phat Bag & Backpack Garment Co. (Vietnam)

Hop Phat boasts over 20 years of expertise in backpack production. The company employs more than 10 office staff and 80 skilled workers. Their products have reached global markets, with exports to over 15 countries including the United States, Japan, Italy, South Korea, and Malaysia.

They offer custom manufacturing services and have a significant production capacity to meet various client needs.

Overview

Location

You’ll find Hop Phat’s operations centered in Ho Chi Minh City, Vietnam. The company has 3 strategically placed factories and shops across the country. This distribution allows Hop Phat to manage its production efficiently and cater to various local and international clients.

Production

Their product range includes:

- Laptop bags

- School bags

- Promotional items

The company’s monthly production capacity is flexible, ranging from 30,000 to 200,000 units. This variability depends on the complexity and design of the products ordered.

Services

You can expect custom manufacturing services from Hop Phat. Their team works closely with clients to ensure the final product matches expectations.

Key Features

MOQ

While it may vary depending on the product, you can generally expect MOQs starting around 100 units.

Timelines

Production timelines can vary based on the complexity of your order. It’s always best to discuss specific timelines with their team when placing an order.

Shipping

Hop Phat offers both domestic and international shipping options. This flexibility allows you to easily distribute your products globally, regardless of your business location.

Quality

They maintain high production standards and use environmentally friendly materials in their manufacturing processes.

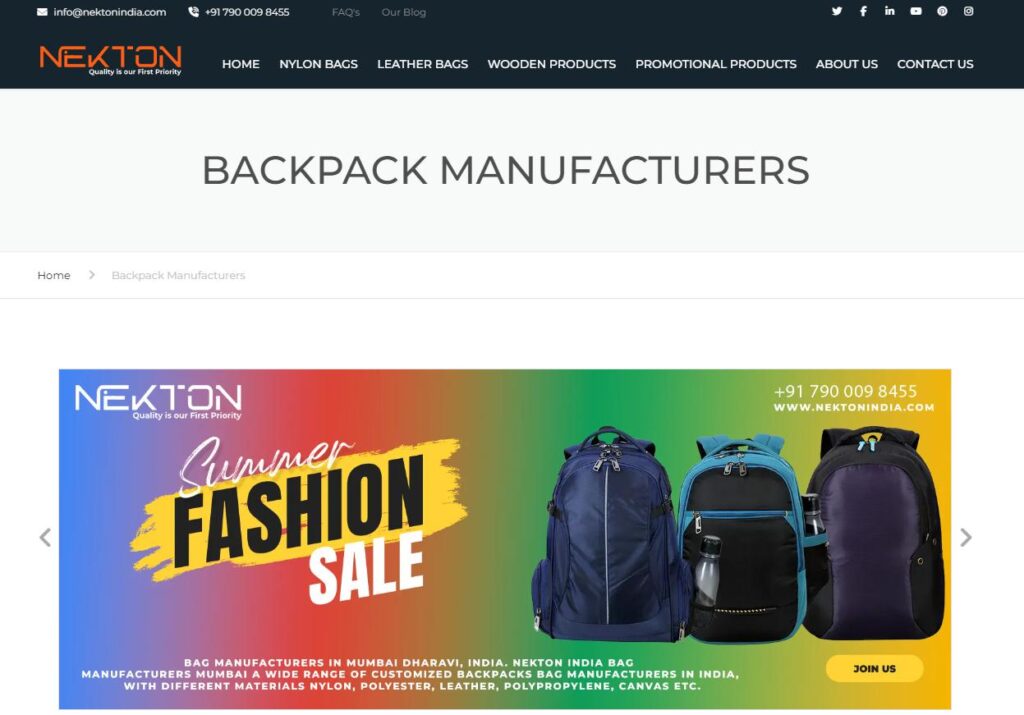

Nekton (India)

Nekton India stands out as a versatile manufacturer of custom bags and promotional products.

Nekton India began its journey with a passion for crafting exceptional bags and accessories. Over the years, they’ve expanded their expertise to include leather goods, wooden products, and promotional gifts.

The company’s strength lies in its ability to work with diverse materials. You’ll find their products made from nylon, leather, and canvas, offering you a variety of options to suit your needs.

Overview

Location

Nekton India’s headquarters and manufacturing facility are located in Dharavi, Mumbai.

Production

They craft a wide array of products, including:

- Nylon bags: backpacks, trekking bags, gym bags

- Leather goods: bags, wallets, laptop sleeves

- Wooden products: boxes, trays, containers

- Promotional gifts

Services

Nekton India offers extensive customization services. You can provide your own designs, drawings, or samples, and they’ll bring your vision to life. They also offer logo embroidery services for promotional items, adding a personal touch to your orders.

Key Features

MOQ

For information about minimum order quantities, you can reach out to Nekton India directly.

Timelines

Production timelines can vary based on the complexity and volume of your order.

Shipping

Nekton India offers both domestic and international shipping options. Quality

They’ve implemented a rigorous four-checkpoint system during production:

- Material cutting

- Logo printing

- Sewing

- Final packing

These checkpoints ensure that each product meets their high standards before it leaves the facility. They also use technical specifications to maintain consistency across their product lines.

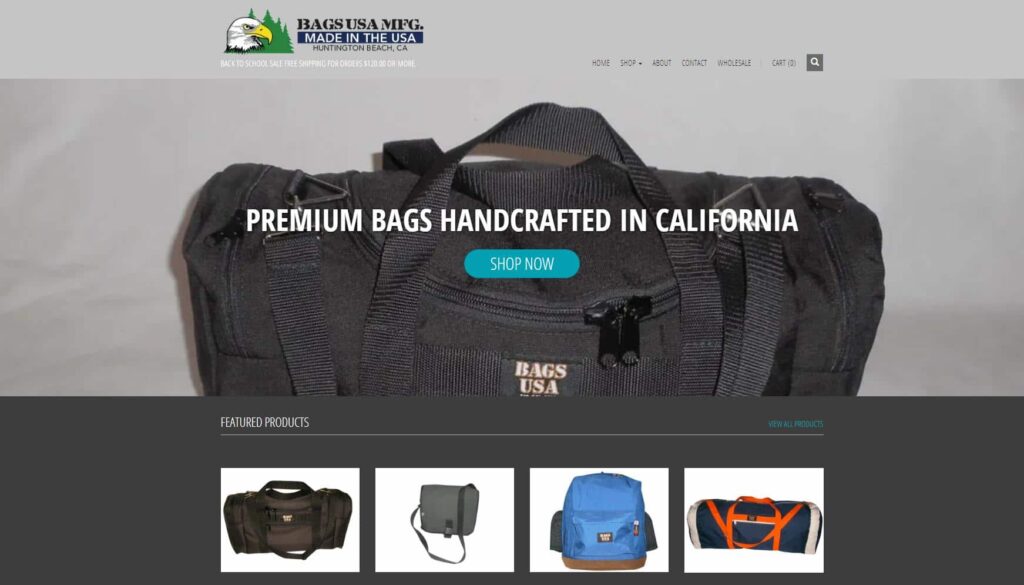

BAGS USA MFG (USA)

BAGS USA MFG specializes in custom bags for sports teams, corporate clients, and government organizations. They offer a wide range of options and pride themselves on high-quality American-made products.

BAGS USA MFG has been in business since 1985, focusing on sport and travel bags. All their products are manufactured on-site in the USA. They cater to a diverse clientele, including soccer, basketball, swimming, cheerleading, dance, hockey, and football teams. Their services extend to disaster relief, medical organizations, businesses, and government agencies.

Overview

Location

Huntington Beach, California.

Production

BAGS USA MFG offers an extensive selection of bag and strap colors. Most of their products are custom-made to meet specific client needs.

Services

BAGS USA MFG offers a wide array of customization options for different bag styles. You can choose from various materials, colors, and designs to create the perfect bag for your needs.

The company uses top-quality industrial fabrics for their bags. These include heavy-duty DuPont Cordura Nylon, 600 Denier Poly, and 400 Denier Nylon. Upon request, they also work with polyester, vinyl mesh, and canvas materials.

Key Features

MOQ

The minimum order quantity at BAGS USA MFG is based on value rather than units. You’ll need to place an order worth at least $500 to work with this manufacturer.

Timelines

Once BAGS USA MFG receives all the necessary materials for your order, you can expect a turnaround time of 2-4 weeks.Shipping

BAGS USA MFG offers both domestic and international shipping options. If you’re in a hurry, they provide a 15-day express service to get your custom bags to you faster.

Quality

The company emphasizes high-quality materials and local manufacturing. By producing all their bags in the USA, they maintain strict quality control standards throughout the production process.

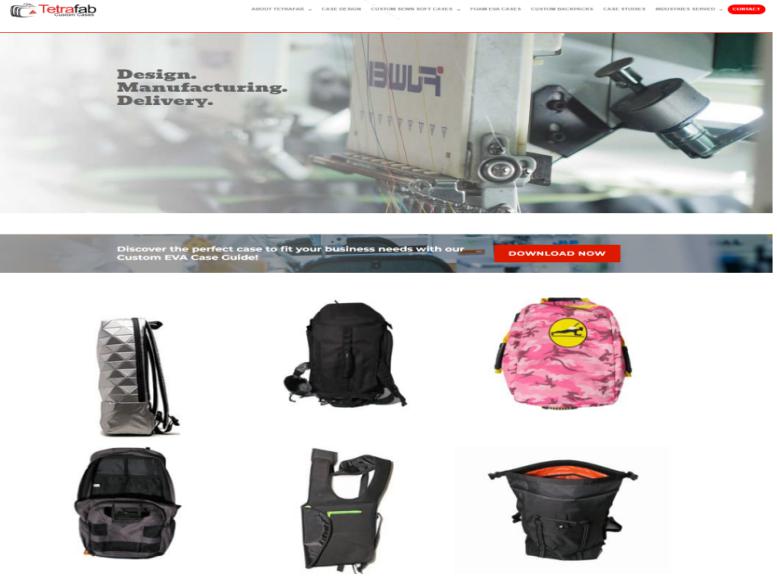

Tetrafab (USA)

Tetrafab has established itself as a premier provider of custom case solutions. Their reputation stems from producing high-quality protective cases for various applications, including electronics, tools, and medical equipment. The company’s skilled team creates cases that blend functionality with durability.

Overview

Location

Tetrafab is headquartered in the USA, with production facilities in Vietnam, Cambodia, and China.

Production

Their product range extends beyond cases to include bags, backpacks, duffels, sleeves, covers, straps, holsters, hybrids, and more.

Services

Tetrafab offers a comprehensive range of services, including:

- Custom case design

- Prototyping

- Bulk manufacturing

- Just-In-Time (JIT) delivery

Their team works closely with clients to bring unique case ideas to life, emphasizing prompt customer service and quick response to inquiries.

Key Features

MOQ

Tetrafab offers flexible Minimum Order Quantities (MOQ) based on product type and customization level.

Timelines

Tetrafab prides itself on quick turnaround times, providing samples in as little as 3 weeks or less. For accurate estimates on full production runs, you’ll need to contact them directly with your specific requirements.

Shipping

Tetrafab provides shipping options for both domestic and international clients. They also offer JIT delivery, allowing clients to focus on serving their customers without worrying about excess inventory.

Quality

They implement a military standard 105-e inspection protocol on all outbound production runs. Additionally, they hand-check entire production runs to ensure each product meets their stringent quality standards.

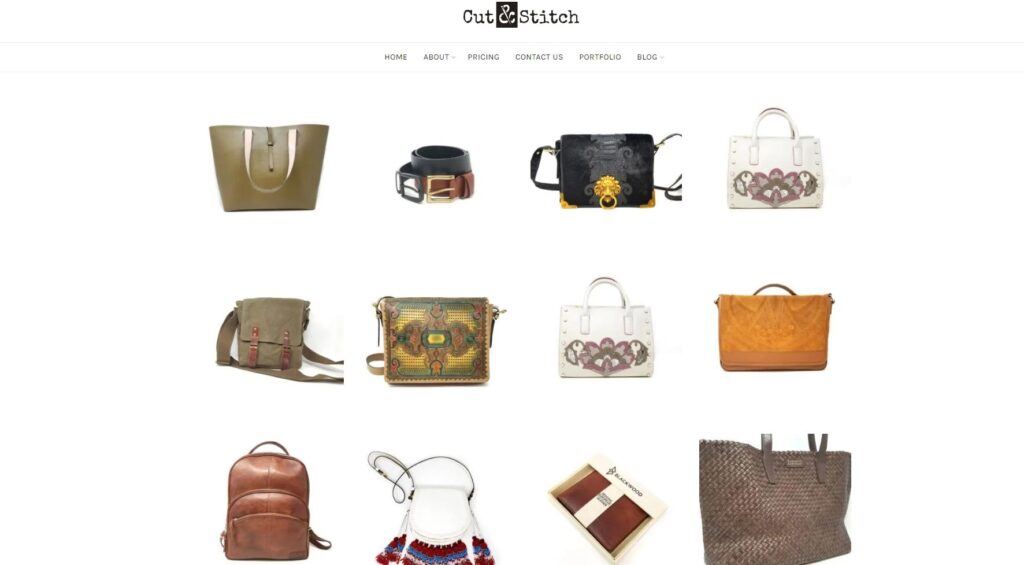

Cut and Stitch (USA)

Cut and Stitch stands out as a leading custom manufacturing company, offering a wide range of services for startups and established brands. They prioritize a vertically integrated manufacturing process, ensuring full control over the supply chain.

Overview

Location

Cut and Stitch is headquartered in New York City, USA, with proprietary factories internationally.

Production

Their product range extends beyond bags and accessories to include all types of clothing apparel and leather goods.

Services

Cut and Stitch offers a comprehensive range of services, including:

- Custom development

- Design services

- Consulting

- Product creation

Their team works closely with clients to bring unique product ideas to life, emphasizing tailored solutions for each brand’s requirements.

Key Features

MOQ

Cut and Stitch offers flexible Minimum Order Quantities (MOQ) to cater to different business sizes.

Timelines

Production timelines at Cut and Stitch vary based on project complexity and size. For accurate estimates, you’ll need to contact them directly with your specific requirements.

Shipping

Cut and Stitch provides shipping options for both domestic and international clients.

Quality

Their vertically integrated process allows for thorough quality control at every stage of production.

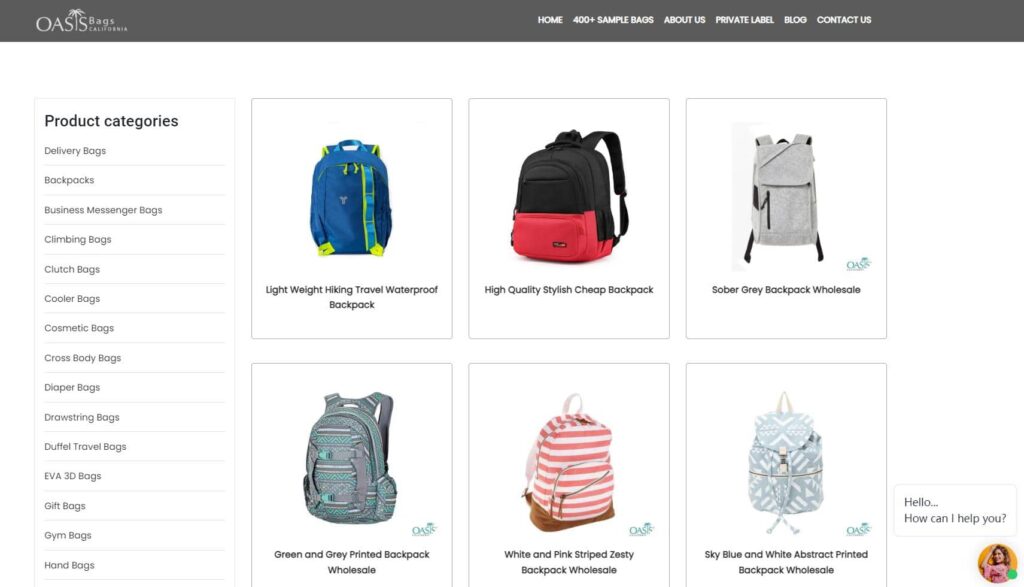

Oasisbags (USA)

Oasisbags has established itself as a leading private label bags manufacturer. Their reputation stems from producing high-end products that meet current style trends. The company’s skilled designers and craftsmen create backpacks that blend minimalism with class.

Overview

Location

Oasisbags operates globally, with offices in multiple countries. You can reach them in the USA, UAE, Australia, and the United Kingdom.

Production

Oasisbags specializes in manufacturing a wide variety of bags, including:

- Fashion designer bags for men and women

- Student bags

- Business bags

- Travel and hiking bags

- Shoe bags

- Diaper bags

- Sports bags

- Wallets and purses

They also operate as a private label bag manufacturer, offering custom solutions for brands.

Services

Oasisbags offers a comprehensive range of services. These include:

- Custom backpack design

- Prototyping

- Bulk manufacturing

- Private labeling

They can customize various aspects such as materials, colors, and features to match your brand’s requirements.

Key Features

MOQ

Minimum order quantities typically start around 100 units, offering flexibility for various business sizes.

Timelines

Custom bulk backpack orders usually take 8-12 weeks for delivery. An expedited air shipping option is available, taking 5 working days but at an additional cost.

Shipping

Oasisbags has a global distribution network. They can ship to various countries, including Canada.

Quality

The company is ISO 9001 certified.

ASG Europe Ltd (UK)

ASG Europe Ltd was founded in 2000, specializing in custom bag design and manufacturing. They’ve built partnerships with clients across retail, sports, technology, industrial, and corporate sectors. Their impressive client list includes well-known names like Umbro, Kappa, Jaguar, and Google.

The company has established long-term relationships with suppliers in key product areas. They work with industry leaders such as YKK, Cordura, UTX Duraflex, NifCo, and ITW Nexus. This network allows ASG to offer high-quality components in their custom backpacks and bags.

Overview

Location

You’ll find ASG Europe Ltd headquartered in Essex, UK.

Production

ASG Europe’s production capabilities are diverse and flexible:

- Technical sports bags from Vietnam

- Lifestyle fashion bags for UK high street brands

- Health & safety bags at their UK factory

- Waterproof Dry Bags produced in China

This flexibility is made possible by their global network of manufacturing facilities.

Services

They collaborate closely with brands to:

- Design custom bags

- Develop prototypes

- Manufacture tailored products

Their team can help bring your vision to life, whether you’re a large established brand or a startup looking to create your first product line.

Key Features

MOQ

The Minimum Order Quantity (MOQ) at ASG Europe Ltd varies based on the product and level of customization.

Timelines

- Design packs typically provided within 48 hours of agreed brief

- Quick submission of raw material samples to support ideas

- First samples ready within two to three weeks after design approval

Shipping

ASG Europe provides both domestic and international shipping options.

Quality

They hold ISO 9001 quality accreditation and work with fully compliant sources. All partner factories provide quality assurance and have been audited by independent organizations like SGS, STR, and Intertek.

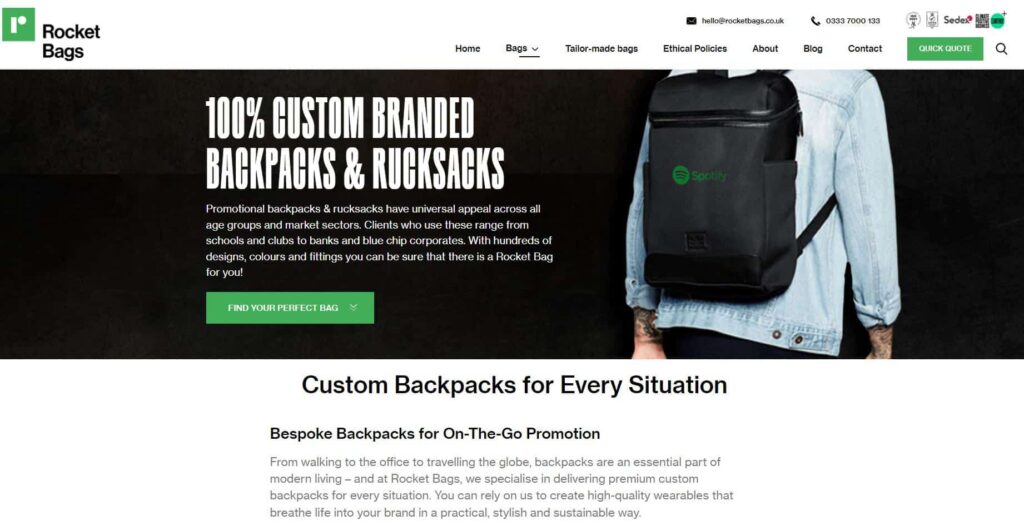

Rocket Bags (UK)

Rocket Bags is a leading custom backpack manufacturer with over 30 years of experience. They specializes in custom-made and bespoke branded promotional bags. They have built a reputation for excellence by serving the UK’s leading organizations.

Overview

Location

Rocket Bags is based in London, UK.

Production

Rocket Bags specializes in manufacturing promotional bags, with a focus on custom backpacks. Their production capabilities cater to various promotional and corporate branding needs.

Services

Rocket Bags offers a comprehensive range of services for custom backpack production. These include:

- Design consultation

- Prototype development

- Bulk manufacturing

- Branding and customization

- Quality control

Their team works closely with clients to bring their ideas to life, ensuring each backpack meets specific requirements and brand standards.

Key Features

MOQ

Minimum order quantities typically range from 300-500 units for custom bags, though this may vary depending on specific requirements.

Timelines

Approximately 3 weeks from design approval to first sample production; Full production and manufacturing of custom bags may take around 6 months.

Shipping

Rocket Bags provides domestic shipping within the UK, with options available for international delivery.

Quality

ISO9001 certified, ensuring high-quality production standards and consistent quality across all products.

Pricing

Rocket Bags claims to offer the best prices in the UK (among ISO 9001 certified companies). They offer a double-the-difference refund if customers find a better price elsewhere, demonstrating their confidence in their pricing strategy.

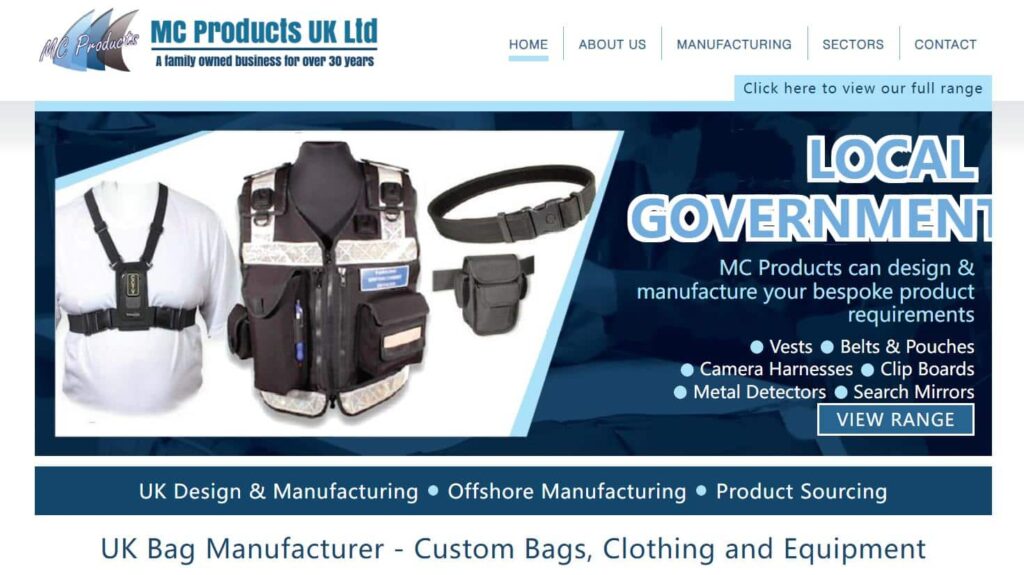

MC Products UK Ltd

MC Products UK Ltd is a leading custom backpack manufacturer with over 30 years of experience. They offer a wide range of personalized bags and equipment for various sectors, including police, security, and emergency services.

Overview

Location

Based in Merseyside, UK.

Production

MC Products UK Ltd offers a diverse range of products including:

- Bags, holdalls & rucksacks

- Thermal & cooler transportation solutions

- Equipment covers & holders

Their custom bags utilize various synthetic materials (e.g., nylon) and natural materials (e.g., leather), catering to different needs and specifications.

Services

MC Products UK Ltd provides comprehensive services including:

- Custom design and manufacturing

- Personalization of holdall bags, cool bags for medicine and catering

- Specialized medical bags (e.g., for carrying oxygen cylinders)

They work closely with clients to create tailored solutions that meet specific requirements.

Key Features

MOQ

Minimum order quantity of 100 units, offering flexibility for various business needs.

Timelines

Production times may vary depending on the complexity and quantity of your order.

Shipping

Flexible shipping options available to meet client needs.

Quality

MC Products UK Ltd places a strong emphasis on quality. Their long-standing relationships with police, security, and prison sectors attest to the durability and reliability of their products.

Frequently Asked Questions

Custom backpack manufacturing involves various aspects, from sourcing suppliers to understanding production processes. Let’s explore some common questions to help you navigate this field.

Which Countries Are the Main Manufacturers of Backpacks, And How Do They Compare?

China leads global backpack production, offering competitive prices and large-scale manufacturing capabilities. Vietnam and India follow, known for their growing textile industries and skilled labor.

The USA specializes in high-end, custom backpacks with top-notch service. European countries like England focus on luxury and designer backpacks.

How Do I Find a Good Wholesale Backpack Supplier in China?

Start by researching online platforms like Alibaba or Global Sources. Look for suppliers with good ratings and customer reviews.

Attend trade shows in China or virtually to connect with potential suppliers. Request samples to assess quality before placing large orders.

Consider working with a sourcing agent who can help navigate language barriers and verify supplier credentials.

What should I look for when selecting a wholesale manufacturer for custom backpacks?

Prioritize manufacturers with experience in custom backpack production. Check their portfolio for similar projects.

Ensure they have quality control measures in place. Ask about their production capacity and lead times.

Look for manufacturers offering design assistance if you need help bringing your ideas to life.

What factors affect the cost of manufacturing custom backpacks?

Materials play a significant role in cost. Higher quality fabrics and hardware increase expenses.

Quantity affects pricing, with larger orders typically resulting in lower per-unit costs.

Customization level impacts price. Complex designs or unique features may require additional labor or specialized equipment.

Production location influences costs. Manufacturing in countries with lower labor costs can reduce overall expenses.

What is the process for producing a custom backpack?

The process begins with design conceptualization. You’ll work with the manufacturer to create your own backpack design.

Next comes prototyping, where initial samples are created and refined.

Once the design is finalized, materials are sourced and production begins.

Quality control checks are performed throughout manufacturing.

Finally, the finished backpacks undergo final inspections before shipping.

Conclusion

Custom backpack manufacturing offers exciting opportunities for businesses and individuals. You can create unique designs that perfectly match your brand or personal style. Many manufacturers provide comprehensive services, from design to production.

Quality and durability are crucial factors to consider. Look for manufacturers using high-grade materials and robust construction techniques. This ensures your backpacks will stand the test of time.

Customization options are nearly endless. You can choose specialized features, colors, and materials to make your backpacks truly one-of-a-kind.

Don’t forget about sustainability. Some manufacturers offer eco-friendly options, helping you reduce environmental impact.

Ready to bring your backpack vision to life? Request a sourcing quote to get started on your custom backpack journey. Expert guidance can help you navigate the manufacturing process and create exceptional products that delight your customers or meet your personal needs.